var bilder = document.getElementsByTagName('img'); for (var i = 0; i < bilder.length; i++) { if (!bilder[i].getAttribute('alt')) { bilder[i].setAttribute('alt', ''); } }

- Gibt es ein Problem?

Bitte kontaktieren Sie uns, um Ihnen zu dienen!

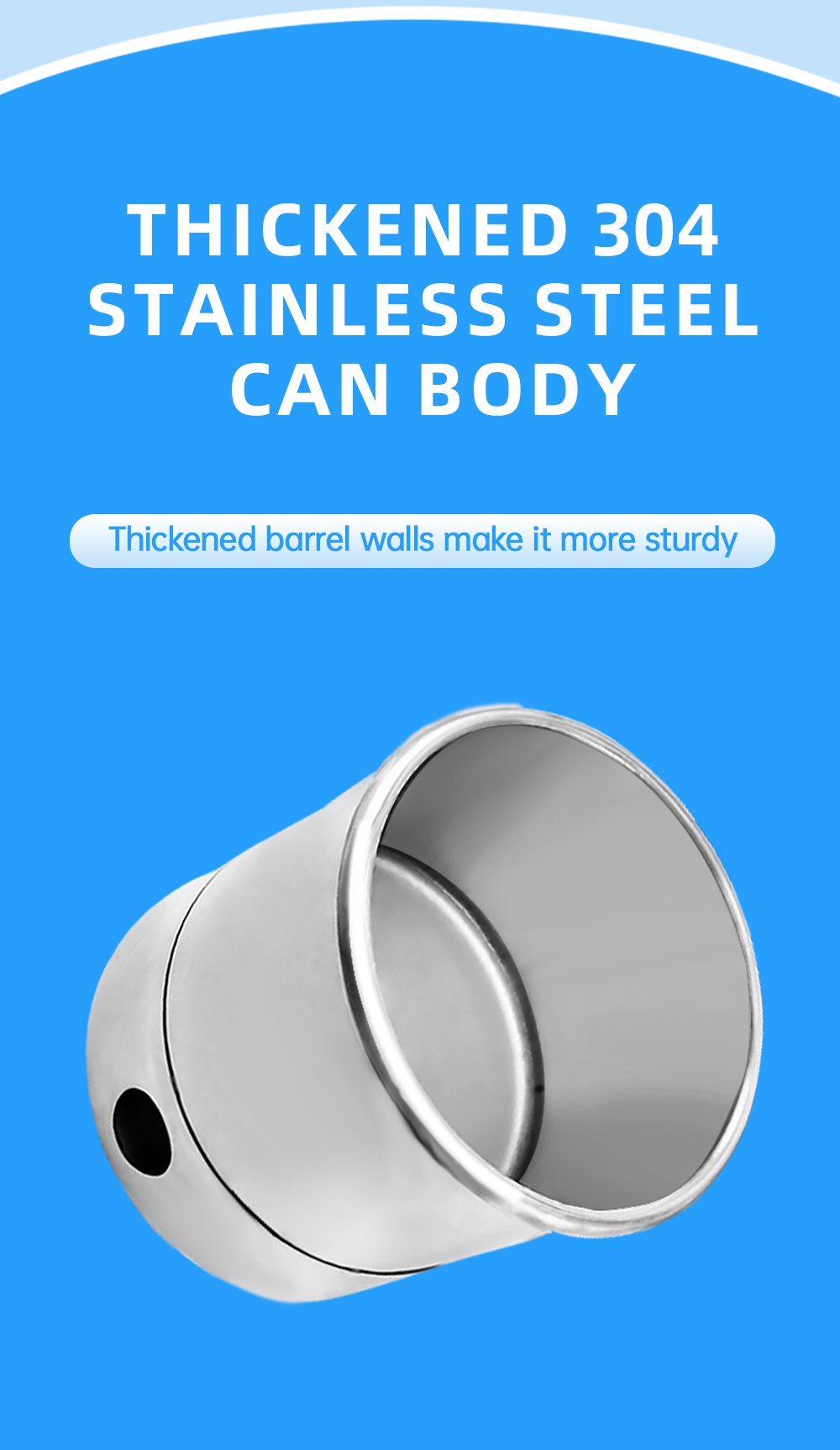

Ein 10-Liter- edelstahl entschäumungseimer vereint spezielle Materialeigenschaften mit einer praktischen Größe für verschiedene Anwendungen.

1. Material: Edelstahl (üblicherweise Qualität 304 oder 316)

korrosionsbeständigkeit: hervorragender Schutz gegen Rost und Korrosion durch Wasser, Chemikalien und Reinigungsmittel. 316 Edelstahl bietet eine überlegene Beständigkeit gegen Chloride und Säuren, wodurch er für aggressive Chemieumgebungen oder maritime Anwendungen geeignet ist.

hygienisch & Leicht zu reinigen: verfügt über eine glatte, nicht poröse Oberfläche, die das Bakterienwachstum verhindert und eine einfache, gründliche Reinigung sowie Sterilisation ermöglicht. Dies ist entscheidend für Anwendungen in der Lebensmittel-, Pharmazeutischen- und Biotechnologiebranche.

langlebig und robust: widerstandsfähig gegen mechanische Belastung, hohe Temperaturen und lässt sich mehrfach verwenden, ohne an Qualität zu verlieren.

2. Kapazität: 10 Liter

Dies ist eine vielseitig einsetzbare, mittelgroße Kapazität. Sie ist groß genug, um eine bedeutende Flüssigkeitsmenge von einem kleinen bis mittleren Prozessbehälter oder Reaktor zu handhaben, bleibt jedoch vergleichsweise transportabel und manuell gut zu bedienen.

Sie ist ideal für labor-R&D im Bench-Scale-Bereich, Pilotanlagen, Kleinserienfertigung und Laborumgebungen.

Diese Ausrüstung ist in jeder Branche unverzichtbar, in der unerwünschter Schaum Probleme verursacht. Typische Anwendungen sind:

lebensmittel- und Getränkeindustrie: in Brauereien (Gärung), Weinkellereien, Saftverarbeitung und Milchproduktion (Mischen, Schlagen).

pharmazeutika & Biotechnologie: schaumkontrolle in Bioreaktoren und Fermentern während der Zellkultur, ohne die Charge mit chemischen Zusatzstoffen zu kontaminieren.

chemische Verarbeitung: in Mischbehältern, Reaktoren und Destillationskolonnen, in denen schäumende Chemikalien verwendet werden.

abwasserbehandlung: zersetzung von Schaum in Belüftungstanks und Behandlungsbecken.

farben & Beschichtungen: verhinderung von Schaum während der Herstellung und Mischprozesse.

klebstoffe & Dichtstoffe: gewährleistung eines schaumfreien Produkts während der Produktion.

Keine Produktkontamination: Führt keine Fremdstoffe (Silikone, Öle usw.) in Ihren Prozess ein und erhält somit die Produktqualität und Reinheit.

Kosteneffizient: Keine wiederkehrenden Kosten für chemische Zusatzstoffe; benötigt lediglich Strom zum Betrieb.

Umweltfreundlich: Reduziert die chemische Belastung im Abwasser.

Gleichbleibende Leistung: Bietet sofortige, bedarfsgerechte Schaumkontrolle ohne Dosierberechnungen.

YCZX produziert und fertigt Entschäumungseimer an. Willkommen, um Entschäumungseimer bei uns maßzuschneidern, Parameter und Abmessungen können alle angepasst werden.