A vacuum cleaner is a very good and helpful device that can help in the clean-up of dirt and dust in your room, also the VUYOMUA's product such as 5 gallon portable air tank. Have you at all been and started pondering the divergent vacuums that are there? A vacuum pump, for example, a mechanical device which is very familiar and more importantly in the industry as it has been of great help in carrying fluids and driving forces and gases pressure. Pressure pump, a second device, but by the way, is also a special case the counterpart. How do vacuum pumps work? Why How in the world do these pumps even work, then?

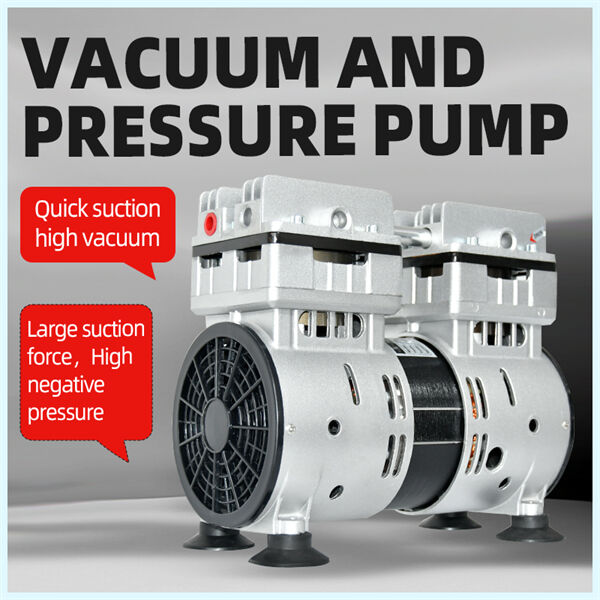

Vacuum Pump: This is when the device performs by creating a vacuum in sealed containers or systems and that creates a low pressure. Adverse this means is when this decrease permits gases and liquids to reserve down on high-pressure zones and then this transport the atmospheric pressure outside. Consider what work does the pump have, in some circumstances is when they have been required to circulate on some of the medical devices and research testing. The air is pulled off of the storage compartments on the enclosure with tubing. In the meantime, another pump is known to be a pressure pump which is to the high-pressure which was develop in a container or a system.

Well, how in the world do these pumps work then? Vacuum Pump: This device works by creating a vacuum in a enclosed container or system leading to lesser pressure within. This decrease permits gases and liquids to go from high-pressure zones over into low-pressure areas which is caused by this. Take into account the work in which vacuum pumps have been required to such as medical devices or scientific tests where air is subsequently drawn off of storage compartments on with tubing for instance.

At the same time, a pressure pump is developed to produce high-pressure within a system or container, along with the vacuum pump for cnc table produced by VUYOMUA. And this is the process in which very high pressure needed example:

- Hydraulic Machine for these it shows its advantages. Higher pressure means that the pump can now transport fluids and gases in small passages, as well as between different areas.

But Here it can be used for the operation of Vacuum and Pressure Pumps

Vacuum and Pressure Pumps must be operated properly Efficient operation is critical in order to manage the pump/media cycle effectively. Proper pump selection, installation and maintenance will go a long way toward maximizing your pumps' performance levels. Following this way can save the time of energy and increase productivity on different operation.

Industries: Food / Beverage Processing, Chemical Manufacturing

One application of this kind are the vacuum pumps, which have taken over an important function in cheese production: During ripening the products automatically remove air, as well as the VUYOMUA's centrifugal extractor fan. The pumps that are used to manufacturing carbonated drinks are the pressure Pump. They pump CO2 into liquid to carbonate the drink.

The range of vacuum and pressure pumps that are available is quite overwhelming so it is important to take into consideration a number of factors when determining which pump will indeed be the most appropriate for meeting requirements, similar to the single phase vacuum pump from VUYOMUA. Such parameters may include the nature of work (or types for which AGV is to be used) and their flow rate while moving different varieties of fluids. Consulting with a professional or the manufacturer of pumps is one way to know which pump would suit you best.

Maintenance of your Vacuum and Pressure Pump Systems

The ideal manner to maintain the efficacy and functionality of vacuum and strain pumps is by taking right care. These are the ones that require cleaning, detecting leaks and then carrying more lengthy analysis to observe for degradation symptoms. When you have an issue or a failure, the faster you deal with it, the less likely something bad is going to happen.

While to a lay person the vacuum and pressure pumps may seem fiddly, in fact they have massive significance across numerous industries, along with VUYOMUA's product ac vacuum pump. Knowing how they operate and using them appropriately will ensure the safe, efficient operation of facilities. Remember, for the best pump results and life of your system contacting professional and distributors is key.

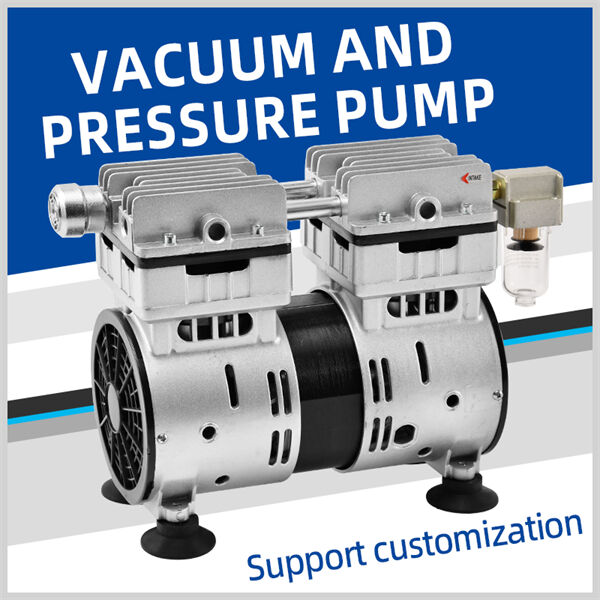

company accredited with American ASME qualifications Chinese TS certification.At the same time, is staffed employees who have more than 10 years vast production experience, which guarantees the stability and quality of items from mechanical equipment to operating. So far, has reliable Vacuum and pressure pumpcustomers both in the US and overseas.

company employs team comprising more than 10 expert design R D engineers with more than 10 years experience in the field equipment and product research development. They can customise various professional products and equipment according to specific customer needs and customers' needs.Meanwhile we have rapid response to sample requests which allows us to swiftly deliver Vacuum and pressure pumphigh-quality samples services.

are a professional vacuum company offering a variety business models that meet requirements various customers. These include: retail, wholesale customized processing. can provide customers with right design solutions for their production equipment as well as high-quality products to meet various customer's sites production Vacuum and pressure pump. offer a range customized product services such as demand analysis, product design, installation of production equipment, and production.

2012, the company's parent is a professional business that a blend of research and development vacuum equipment as well as the sales production that has nearly 13 years of experience in the field vacuum. over 13 years of industry experience, the company has solid track record in production, Vacuum and pressure pumpand sales has accumulated many loyal customers. A large scale of procurement standard production offer us enormous costs and allow us to offer customers the best items services at most competitive costs.