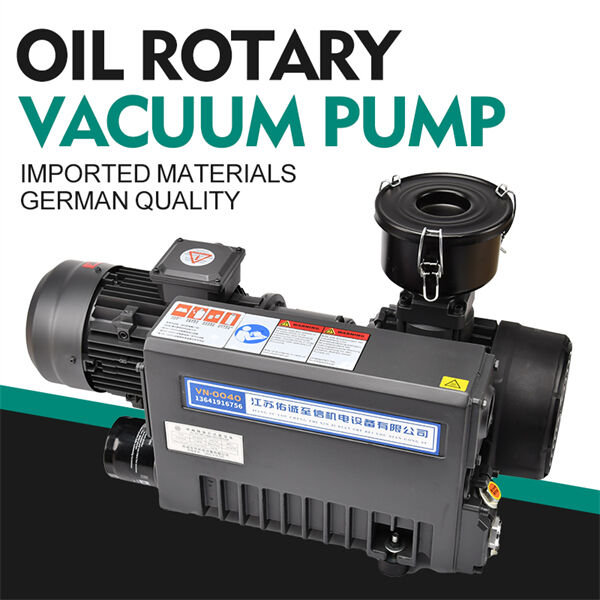

The oil rotary vacuum pump is a specific machine that functions from spinning vanes and oil to develop an area without air. The oil follows the vanes as it moves, helping provide a near perfect seal on internal chamber of pump eliminating any air vacuum in the area.

This also affects your choices when it comes to selecting oil for the pump. Every oil is different and the difference in oils means that you need to make sure you have selected a type of formulation which will best meet your pump requirements. The viscosity of certain oils may be either too thick or too thin, which can affect how well the pump works. Winding up, make sure that you take a look at the instructions which come with your pump before choosing an oil.

This requires regular maintenance of your oil rotary vacuum pump in order to obtain maximum performance form it. You know, like looking after oil changes and keeping an eye out for underbody leaks... Also remember it is important to keep the pump clean and debris free. This information, along with many other manufacturers recommendations for maintenance of the pump, can be supplied by the manufacturer.

If you begin to hear any unusual noises then your pump may be struggling and it is time for some troubleshooting. Leaking, vane erosion and blocked filters are common issues. In order to prevent the pump from causing more damage, these issues need to be solved as soon as possible.

There are numerous benefits when using an oil rotary vacuum pump in industrial or commercial applications. These pumps are extremely reliable and can run non-stop for days on end. The razors are also relatively inexpensive and parts that must be replaced are readily available. Oil Rotary Vacuum Pumps are commonly used in industry, research facilities and clinics.

In conclusion, an oil rotary vacuum pump remains irreplaceable in different industrial and commercial applications. In order to make full use of the equipment, users must understand how it operates in addition to what kind of oil should be used and how maintenance procedures are performed as well as troubleshooting errors or recognizing its advantages. Users should follow these instructions meticulously to get years of trouble-free use out of your oil rotary vacuum pump.

company has American ASME qualifications Chinese TS certification.At the same time, company has group of employees with over 10 years vast production experience, which guarantees the quality stability products from mechanical equipment to the operators. As of now, it has a group loyal and oil rotary vacuum pumpcustomers across the globe and at home.

company's parent company established in 2012. It a professional firm that involved in research and development, manufacturing, sale of vacuum machines. have nearly 13 years experience within vacuum sector. company, with almost 13 years industry experience is well-versed in sales, production and procurement. company has also built a loyal customer base. able to provide our customers with high-quality oil rotary vacuum pumpand services at the most affordable price due to large-scale production and procurement.

company oil rotary vacuum pumpteam more than 10 professional designers and R D engineers over 10 years' experience in field of equipment and product research and development. can customize various professional products and equipment according to the needs different customers to meet customer needs.Meanwhile, we have an efficient sample response process enables us to quickly provide customers with high-quality sample services.

are a professional vacuum firm provides a range business models that meet needs of different customers. They include wholesale, retail custom processing. company offers customers quality production equipment design solutions compatible with their site production needs. The company provides oil rotary vacuum pump set of product customization service solutions: starting demand analysis, through product selection, draft design ,and installation of equipment for production from product development to product delivery delivery, providing you with an all-in-one solution customizing your product for vacuum equipment.