The asynchronous motors, also known as induction motors are largely utilized in multiple industries primarily on the account of their price and green feature. These motors have been primarily used to convert electrical power into mechanical power, providing a key element in the functioning of an assortment industrial machinery and equipment.

Frequecy-sensitive motors operate by creating a magnetic field utilizing electromagnetic principles, which provides the basis of an energy transfer. A stator is a stationary component within the alternator that generates the magnetic field, which in turn drives an armature or rotor to spin together. This happens through two magnetic fields being created between the stator and rotor as they catch on to each other, ultimately torquing & rotating the rotor.

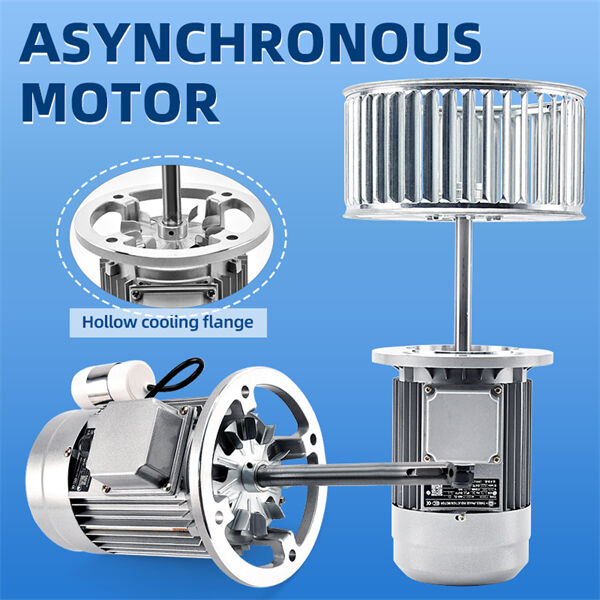

The simplicity and reliability of synchronous motors give them an edge over other types off theese type of motors. Their design makes it possible to avoid the use of brushes, commutators or slip rings and this eliminates many wear problems associated with other motor types. Because there are fewer elements that must move in an asynchronous motor, it is able to operate more efficiently and innovatively than synchronous motors while requiring less maintenance. This makes them a favoured option inside industrial environments.

Benefits of Asynchronous Motors for Use in the Industry The use of asynchronous motors has become popular, both and that is due to their cost-effective nature as well as because they are highly efficient (reliable) as well. Indeed, asynchronous motors are much more energy-efficient than alternative motor options with efficiency rates as high as 90% and above. Just as important, however, is their ability to provide the power needed - in terms of torque and speed - for large-scale industrial applications.

A second important advantage of induction motors: undoubtedly the almost universal arrangement. Available to be run on both AC and DC power sources, they are applicable in numerous industrial applications. They are widely used in fans, pumps, compressors conveyors and mixers etc. industrial machinery.

The automotive sector, therefore, remains one of the largest users for asynchronous motors and is used in a broad spectrum ranging from power steering to windshield wipers, fuel pumps up to HVAC systems. In addition, synchronous motors are also what power (literally) electric and hybrid vehicles with their asynchronous cousins spinning the wheels that need to be spun at a determined speed of torque. This is because this type has a better torque-to-weight ratio, it costs less and also lower maintenance across the range compared to alternatives.

With continuous motors, they are used in vehicle charging systems for electric vehicles; this allows rapid and efficient EV charging. The motors allow for high power density to get the vehicle charged quickly-and they are low-maintenance and expected to be among the most reliable parts of an electric car.

There are a number of different types on the market, and whether you're looking for one in an industrial context - from AC use to phase conversions or simple motor speed control systemsto name just three application areas- there is no shortage out there when choosing between them. In addition to that, they need to keep the following points in mind:

Power factor: This measures how efficiently the motor converts electrical power into mechanical work. They are more energy efficient that reduced the costs of motors as well.

Enclosuer Type: The enclosure of a synchronous motor is available in various types such as totally enclosed, open drip-proof and explosion proof. The choice of enclosure type will depend on the operating environment and protection level required.

Output Speed: Professionals from transformer manufacturing industry believe that the output of an asynchronous motor depends on number poles and frequency in its power supply. Motors with higher poles count offer lower speeds but more torque, and if they have less pole counts hyperlinked to them provide way too high spin rates but drastically smaller amounts of torque.

To sum up, asynchronous motors are an excellent alternative for a lot of applications; they build on them their low price point and being reliable hormones. To ensure that your asynchronous motor is the best option for use and performance, it must have been carefully evaluated in terms of operating environment, torque desired speed at which you will get power from. These professionals in the field of motor supplies will advise you on how to go about finding the right motor for your needs.

company has American ASME qualifications Chinese TS certification.At the same time, company has group of employees with over 10 years vast production experience, which guarantees the quality stability products from mechanical equipment to the operators. As of now, it has a group loyal and asynchronous motorcustomers across the globe and at home.

company asynchronous motorteam more than 10 professional designers and R D engineers over 10 years' experience in field of equipment and product research and development. can customize various professional products and equipment according to the needs different customers to meet customer needs.Meanwhile, we have an efficient sample response process enables us to quickly provide customers with high-quality sample services.

parent company was founded in the year 2012. is a professional firm that is involved in research and development, production, sales of vacuum equipment. have nearly 13 years experience vacuum sector. With nearly 13 years of industry experience, the company has solid asynchronous motorin production, procurement and sales has accumulated a group of loyal customers. large-scale procurement as well as standardization of production give huge product costs and allow us to offer clients the top items and services at best price.

a highly professional asynchronous motorwith its roots the field of vacuum order serve different types of customers, we provide various types business models, including wholesale, retail and custom processing. can provide customers with efficient design solutions their production equipment and high-quality products according different customers' site production requirements. We provide wide array of custom-designed product services such as demand analysis, design, installation of production equipment and production.