var images = document.getElementsByTagName('img'); for (var i = 0; i < images.length; i++) { if (!images[i].getAttribute('alt')) { images[i].setAttribute('alt', ''); } }

- Är det nåt problem? - Nej.

Kontakta oss för att få service!

E "5L rostfri stålbägare för avskumning, oljefri vakuumavskumningsbägare" beskriver en laboratorie- eller pilotanläggning som kombinerar mekanisk centrifugal avskumning med vakuumtryck för att uppnå ultraeffektiv, fritt från föroreningar, skumborttagning, avgörande för högprecisionindustrier.

Denna maskin är utformad för att ta bort luftbubblor (avskumning/avluftning) från viskösa vätskor (t.ex. harter, färger, kaka, epoxi) utan att introducera någon oljeförorening från pumpar. Den använder en tvåstegsprocess:

centrifugal avskumning: en snabbt roterande platta skapar centrifugalkraft, som sprider ut materialet till en tunn film och kastar tyngre komponenter utåt. Luftbubblor, som är lättare, separeras och stiger till ytan där de spricker.

vakuum avskumning: a vakuumpump sänker trycket inne i kammaren. Detta minskar kraftigt volymen av eventuella återstående luftbubblor som är kvar, vilket får dem att expandera, snabbt stiga och kollapsa.

Kombinationen av dessa två metoder är mycket effektiv för envisa, fina bubblor i tjocka vätskor.

kapacitet: 5 liter. Detta är en bänkstorlek, perfekt för forskning och utveckling, prototypframställning och liten serieproduktion .

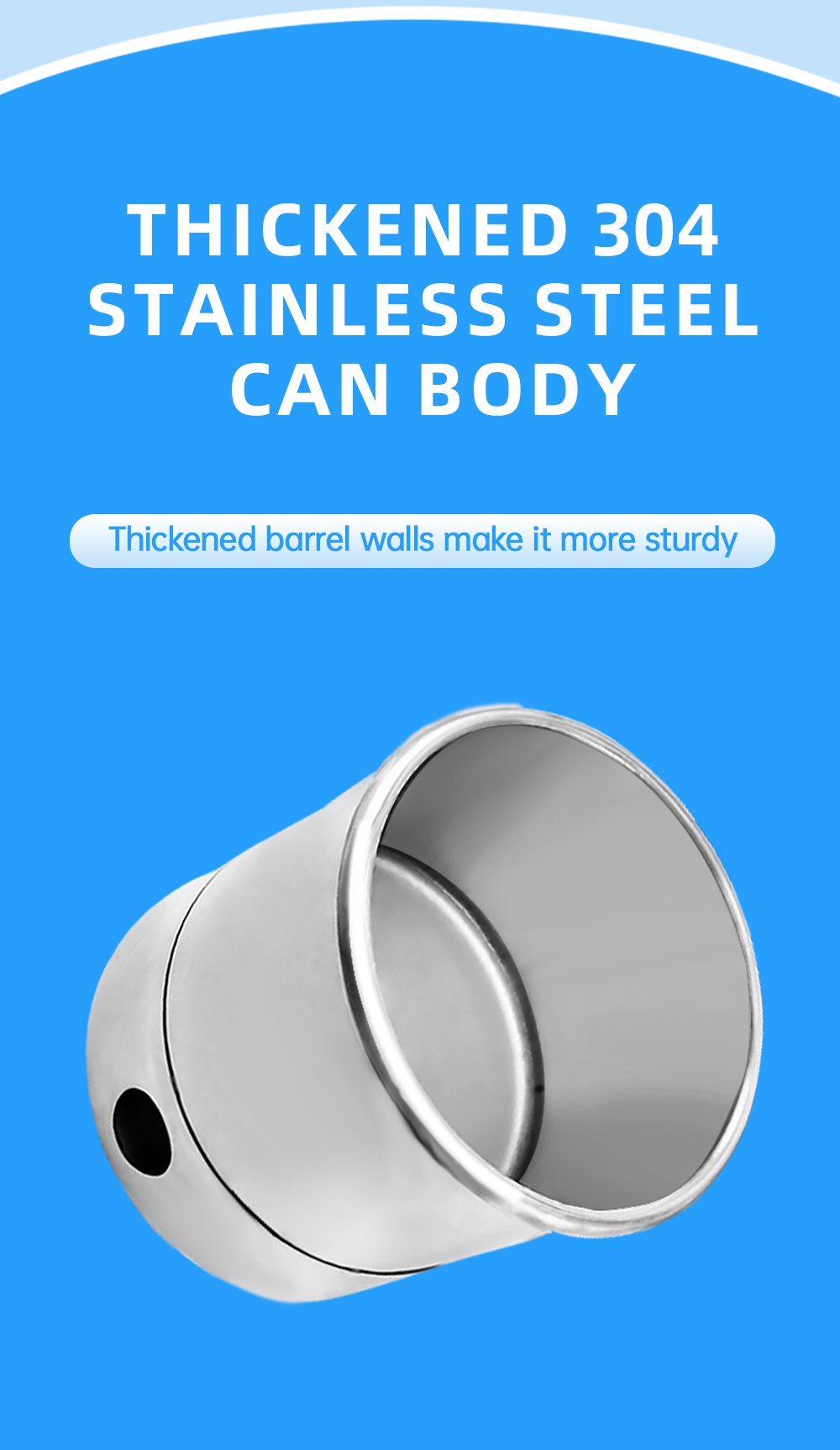

material: - Jag är inte... rostfritt stål (kvalitet 304 eller 316). detta säkerställer:

korrosionsbeständighet mot kemikalier.

Enkel rengöring och sterilisering.

hållbarhet och lång livslängd.

Denna maskin används inom industrier där eliminering av mikro-bubblor är avgörande för produktens prestanda och kvalitet:

Elektronik: Kapslingshartsar, gjutmassor, underfyllningsmaterial, ledande bläck och pasta.

Optik & LEDs: Optiska linser, LED-förpackningsharts, samt limfilmer där bubblor orsakar ljusspridning eller defekter.

Tryck & beläggningar: högvärdiga bläck, pigment och beläggningar för precisionsapplikationer.

medicinsk och farmaceutisk: silikongeler, medicinska limmedel och biokompatibla pastor.

avancerade material och forskning: nanomaterialsörjer, keramikpaster och kompositmaterial.

hög effektivitet: den dubbla centrifugal- och vakuumverkan tar bort även de minsta mikrobubblorna.

ingen kontamination: vakuumet utan olja säkerställer att produkten förblir ren.

konstant kvalitet: producerar blåslefria, homogena produkter, vilket är avgörande för prestanda och utbyte.

kompakt och användarvänlig: 5 liters storlek är idealisk för laboratoriemiljöer.