Important Considerations for Air Receiver Tanks in Compressed Air Systems

As a critical component in compressed air systems, the air receiver tank serves several key functions, such as storing air, stabilizing pressure, reducing pulsations, and removing moisture. Here are some important precautions for maintaining air receiver tanks:

Avoid Oil Accumulation in the Tank

Most industries use oil-injected screw compressors, meaning the compressed air contains oil particles. These can accumulate in the receiver tank, mixing with dust and rust to form sludge, which can degrade air quality and contaminate downstream equipment. Regular draining of the tank and proper filtration of the incoming air are essential.Minimize Vibration in the Piping System

The intermittent operation of compressors causes pressure and airflow fluctuations, which can lead to vibration in the air piping. If the air receiver tank is not properly installed, such as not being securely mounted or the piping being incorrectly positioned, this vibration can cause leaks at connection points, leading to energy inefficiencies.

Equip the Tank with Safety Accessories

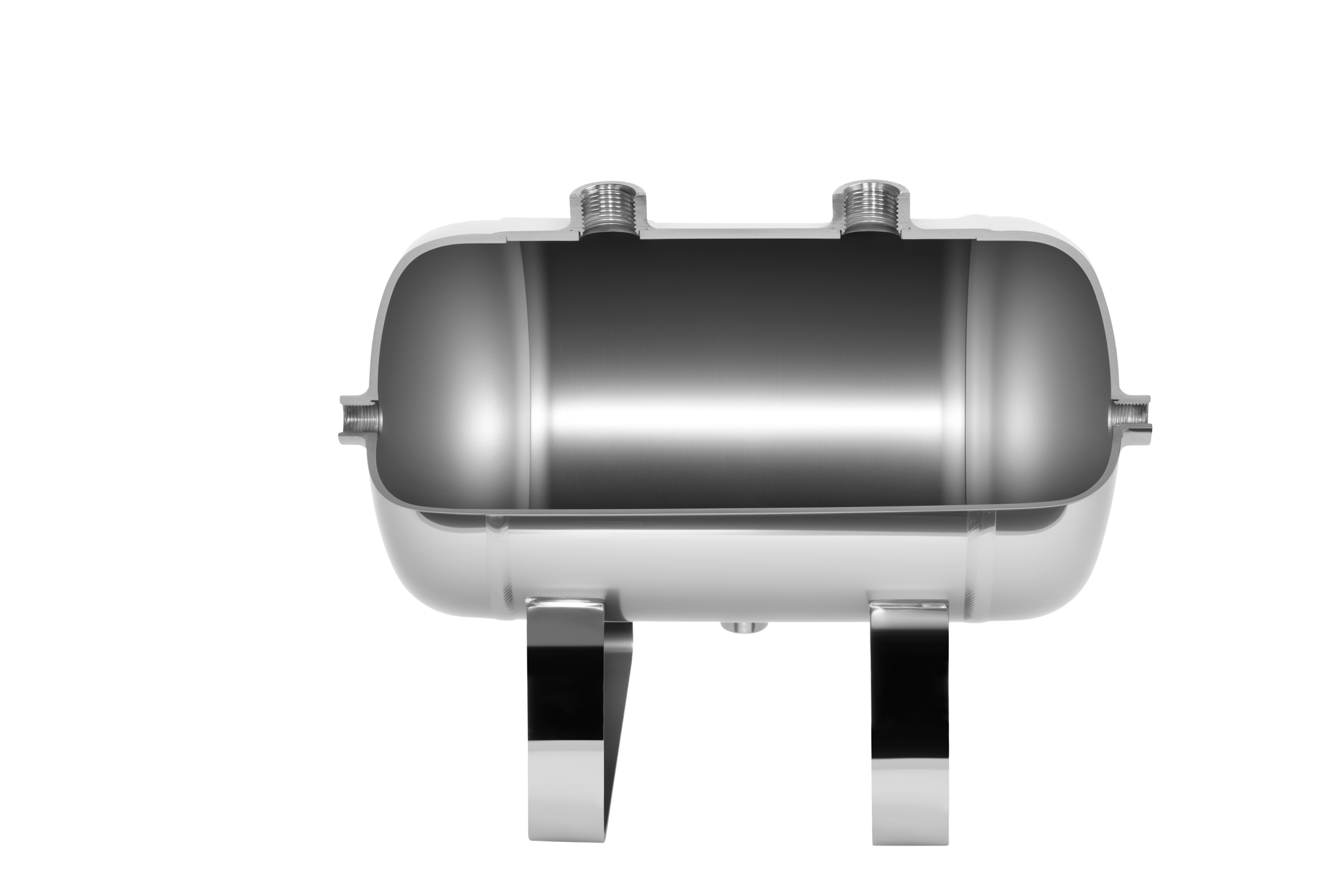

Pressure vessels must be equipped with safety devices such as pressure relief valves and pressure gauges. For piston compressors, check valves should be installed between the compressor and the receiver. A silencer should also be placed between the check valve and the tank. Although no shutoff valve is needed between the compressor and receiver, a shutoff valve is required between the receiver and the supply line.Ensure Proper Material and Sizing

When purchasing an air receiver tank, it’s important to confirm the required air capacity and pressure rating. Choose a reputable manufacturer to ensure the tank is made from high-quality materials with uniform steel thickness and reliable welding. Poor quality tanks can lead to operational issues in the long run.