var images = document.getElementsByTagName('img'); for (var i = 0; i < images.length; i++) { if (!images[i].getAttribute('alt')) { images[i].setAttribute('alt', ''); } }

A 10L baja tahan karat ember penghilang busa menggabungkan sifat material tertentu dengan ukuran yang praktis untuk berbagai kegunaan.

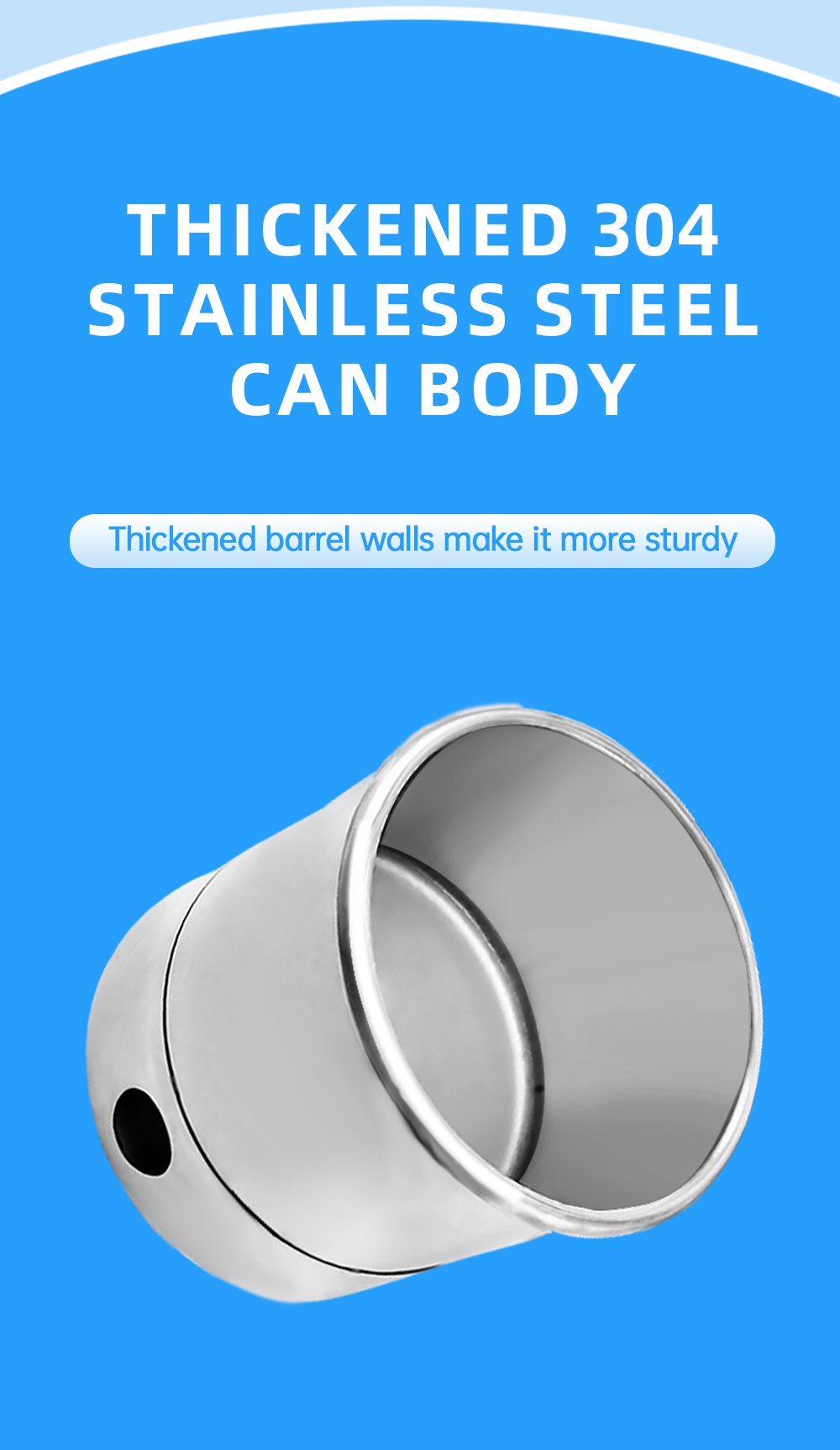

1. Material: Baja Tahan Karat (Biasanya Bergradasi 304 atau 316)

Tahan Korosi: Ketahanan yang sangat baik terhadap karat dan korosi dari air, bahan kimia, serta pembersih. Baja tahan karat 316 menawarkan ketahanan yang lebih baik terhadap klorida dan asam, menjadikannya cocok untuk lingkungan kimia yang keras atau aplikasi maritim.

Higienis & Mudah Dibersihkan: memiliki permukaan yang halus dan tidak berlubang yang mencegah pertumbuhan bakteri dan memungkinkan pembersihan dan sterilisasi yang mudah dan menyeluruh. Hal ini sangat penting untuk penggunaan makanan, farmasi, dan bioteknologi.

kuat dan tahan lama: tahan terhadap dampak fisik, suhu tinggi, dan penggunaan berulang tanpa degradasi.

2. Kapasitas: 10 liter

Ini adalah kapasitas menengah yang serbaguna. Ini cukup besar untuk menangani volume cairan yang signifikan dari tangki proses kecil hingga menengah atau reaktor tetapi tetap relatif portabel dan mudah dikelola secara manual.

Ini ideal untuk r&D skala bench, pabrik percontohan, produksi batch kecil, dan pengaturan laboratorium.

Peralatan ini sangat penting di industri mana pun di mana busa yang tidak diinginkan menyebabkan masalah. Penggunaan umum meliputi:

makanan & Minuman: di pabrik bir (fermentasi), pabrik anggur, pengolahan jus, dan produksi susu (pencampuran, penjilat).

Farmasi & Bioteknologi: Mengendalikan busa di dalam bioreaktor dan fermentor selama kultur sel tanpa mencemari batch dengan aditif kimia.

Pengolahan Kimia: Di dalam tangki pencampur, reaktor, dan kolom distilasi di mana bahan kimia yang menimbulkan busa digunakan.

Pengolahan Air Limbah: Memecah busa di dalam tangki aerasi dan bak pengolahan.

Cat & Pelapis: Mencegah terbentuknya busa selama proses produksi dan pencampuran.

Perekat & Segel: Memastikan produk bebas busa selama proses produksi.

tidak Ada Kontaminasi Produk: tidak menambahkan zat asing (silikon, minyak, dll.) ke dalam proses Anda, sehingga menjaga kualitas dan kemurnian produk.

efisien Secara Biaya: tidak ada biaya berkala untuk aditif kimia; hanya memerlukan listrik untuk menjalankannya.

ramah Lingkungan: mengurangi beban kimia dalam limbah cair.

kinerja Konsisten: menyediakan kontrol busa yang segera dan sesuai kebutuhan tanpa perlu perhitungan dosis.

YCZX memproduksi dan melakukan kustomisasi defoaming bucket. Selamat datang untuk melakukan kustomisasi defoaming bucket bersama kami, parameter maupun dimensi semuanya dapat dikustomisasi.