Cost-effective air storage tanks from original air tank manufacturer 10L/20L and 25L air tanks

The air tank cost mainly consists of the material cost, manfucturing & labor cost, factory operation cost and testing/certification cost.

For material cost, it refers to the steel plates cost (carbon steel/ stainless steel/aluminum), and components cost ( valves, fittings, gauges, handles, and brackets etc). The cost fluctuates with global steel prices, and order quantity. The air tank factory has no way to reduce the cost.

For manufacturing and labor cost, the air tank manufacturing process mainly includes:

Fabrication: metal cutting, shape forming and ends doming.

Welding: The most critical and skill-intensive step. High-quality, certified welders are required, especially for pressure vessels. Automatic welding increases initial capital cost but improves consistency.

Heat Treatment: Many air tanks undergo heat treatment (annealing) to relieve stresses from welding and forming.

Surface Preparation & Painting:Blasting, cleaning, and applying corrosion-resistant paint or powder coating.

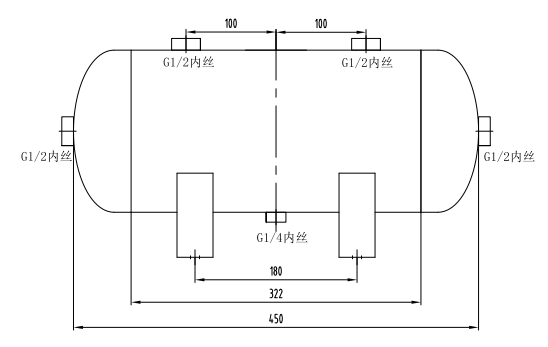

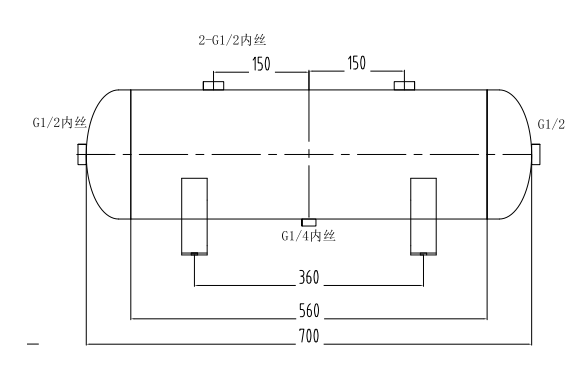

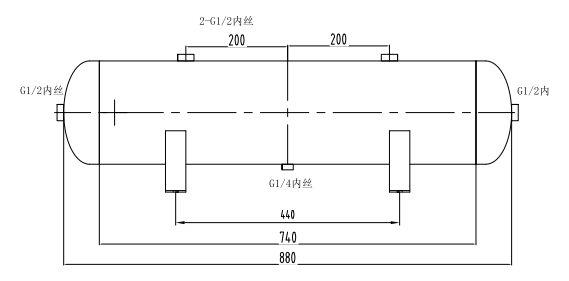

All above process depends much on manpower, so the labor cost is high, while in china, labor cost increases day by day, so it is essential to introduce automatic production lines. YCZX has established an automatic production line for 10L, 20L and 25L air tanks. In this production line, from fabrication to painting, is totally automatic, so the capacity is big , and has very competitive price due to no labor cost. Welcome to contact us to order these air tanks, we will offer best price base on order quantity.

Quality Control & Testing cost, for pressure vessels, each air tank must be hydrostatically tested and pass X-Ray/Welding Inspection. It is non-negotiable cost for air tank factory.

Certification is a critical cost especially for high-pressure tanks,such as ASME, CE certifications etc, the air tank manufacturer must pay fees to 3-rd certifying bodies and undergo regular audits.

Therefore, for air receiver tank manufacturers, the controllable cost only in manufacturing and labor cost, which requires the air receiver tank manufacturers to keep improving production effiency. YCZX always on the way to achieve this goal.