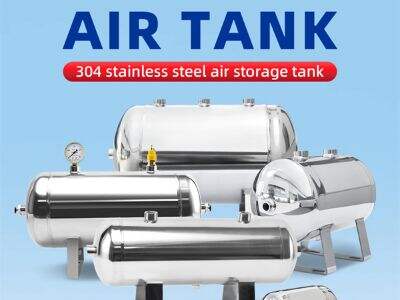

One of these is the air storage tanks that are crucial for keeping air ready for a good many purposes. These YCZX asme stainless steel air tank are made out of different materials and the two most common material types include carbon steel and stainless steel; in this blog we will compare these two material from stainless steel air storage tank being considered a good option over the carbon as well.

Comparison of Carbon Steel and Stainless Steel for Air Storage Tank

Materials for making air storage tanks are usually carbon steel or stainless steel. Nevertheless, the two are not one in the same. While carbon steel is a strong, and durable material compared to stainless steel, it does tend to rust. On the other hand, stainless steel is more rust and corrosion-resistant so you can store any kind of air or gases in and from it.

Why Stainless Steel Outperforms Carbon Steel In Rust And Corrosion Protection?

The biggest benefit to stainless steel versus carbon steel is the higher resistance to rust and decay. Susceptible to rust: Stainless steel has chromium in its ingredients, this results the rebound of chromium on the outer surface, protecting it from forming a rust. That is why the air stored in a stainless steel tank will be contaminated with rust particles to a lesser extent, thus being of a higher quality for various atomic operations.

The Savings Over Time Of Stainless Steel Air Storage Tanks: Air storage tanks are the base and source of pressure for your air compressor system.

Though stainless steel is a more expensive material upfront compared to carbon steel, it ends up paying for itself in the long term. YCZX stainless air tank is a look that many prefer because it needs less upkeep and does not corrode in the long run, something that carbon steel might do. However, when companies decide to use stainless steel as their material of choice for air storage tanks, they save on maintenance costs because such tanks are guaranteed to last long after their purchase.

Must know how to maintain each material in order to perform its best.

As with all carbon steel and stainless steel tanks, they require maintenance to continue running effectively. Checker plate steel tanks made from carbon steel (C1020) may need to be inspected often for rust or corrosion and potentially repainted or coat with appropriate treatment. Stainless steel tanks are generally lower-maintenance and do not have to be checked as often. But you will need to clean and inspect your stainless steel tanks at regular intervals in order to keep them strong.

Material selection and its impact on stored air quality in tanks.

In addition, the material selected for air storage tanks can impact the purity of the stored air. RustParticulatesCarbonSteel Rust Particulates Carbon Steel tanks more likely to corrode. Stainless steel tanks, however, do not and will not leach contaminants into the air. This is useful for industries wherein their processes will necessitate clean air no matter what, like food production or pharmaceuticals.

To sum up, stainless steel a better material option than carbon steel for air storage tanks. In addition, it provides corrosion resistance, reduces maintenance and keeps your stored air free of contamination. The industrial storage of air is supported by stainless steel tanks and over the long term, they contribute to saving money which reinforces their performance in choosing them for use across various operations. If you need high-quality air storage tanks, please contact YCZX to purchase the durable stainless steel air tank that is best in line with your requirements.

Table of Contents

- Comparison of Carbon Steel and Stainless Steel for Air Storage Tank

- Why Stainless Steel Outperforms Carbon Steel In Rust And Corrosion Protection?

- The Savings Over Time Of Stainless Steel Air Storage Tanks: Air storage tanks are the base and source of pressure for your air compressor system.

- Must know how to maintain each material in order to perform its best.

- Material selection and its impact on stored air quality in tanks.