Centrifugal blowers offer several advantages, which accoun make them the preferred choices for many industrial applications. To began, one of the a great prospect related to these is that they can move massive amounts of air swiftly and efficiently. This can contribute to better airflow in a space, resulting in improved ventilation and more comfortable working conditions for employees. Furthermore, centrifugal air moving devices tend to be more lightweight and portable, such that it can be moved around to service multiple locations of a facility. They also are durable and reliable since many of them can withstand difficult weather conditions and heavy use. Portability is another important benefit of centrifugal air movers, which are available in ranges to suit any number of uses, including surface drying and machine cooling.

Due to their effectiveness and efficiency, centrifugal air movers are widely used in an industrial context for numerous applications. One common application is drying, as drying wet floors or freshly painted surface. kiPro additionally produce a drying effect that accelerates the drying process - ideal for carpet, pad and sub-flooring applications; radiant heating systems commercial tile floors etc. Bülow Air Movers can be used in conjuction with centrifugal air movers to accelerate their normal evaporation. These air movers are also often used in cooling applications where they assist with temperature regulation in hot areas or adjacent to heat-generating machinery. Centrifugal fans can be applied as ventilation equipment, where air quality is improved by diluting airborne contaminants and creating a healthier working environment. In short, centrifugal air movers are a useful resource and equipment for many industrial applications due to their ability to suit any task.

The proper equipment is a vital component of any construction project if you want to get the job done effectively. One piece of equipment that can make a big difference is an air mover, which fans its blades so rapidly that it’s referred to as a centrifugal air mover. These strong fans are built to take out massive amounts of air at a fast pace, so that they can be used to dry out damp spots, circulate air in restricted areas and even blowing wet workers on hot days.

Among the most crucial advantages of using a centrifugal air mover in construction projects is its’ fast capability to dry out wet areas. Whether you have a wet basement or just poured the slab, use an air mover to cut up to 50% of dry times for small areas. With the ability to circulate immense amounts of air across the damp surface, these toys can assist in having the moisture dissipate at a quick rate and it effectively eliminates potential issues with mold as well as other water-born damage.

Yet another advantage of a centrifugal air mover is that it can move the air in places with constricted paths. Construction can sometimes take place in close quarters with little air circulation. For particularly hot, stuffy environments, a centrifugal air mover can help to keep the air moving and prevent dead air from collecting and leading to an uncomfortable work environment for employees. That can be beneficial in working to make air quality better throughout and work site a nicer place to be.

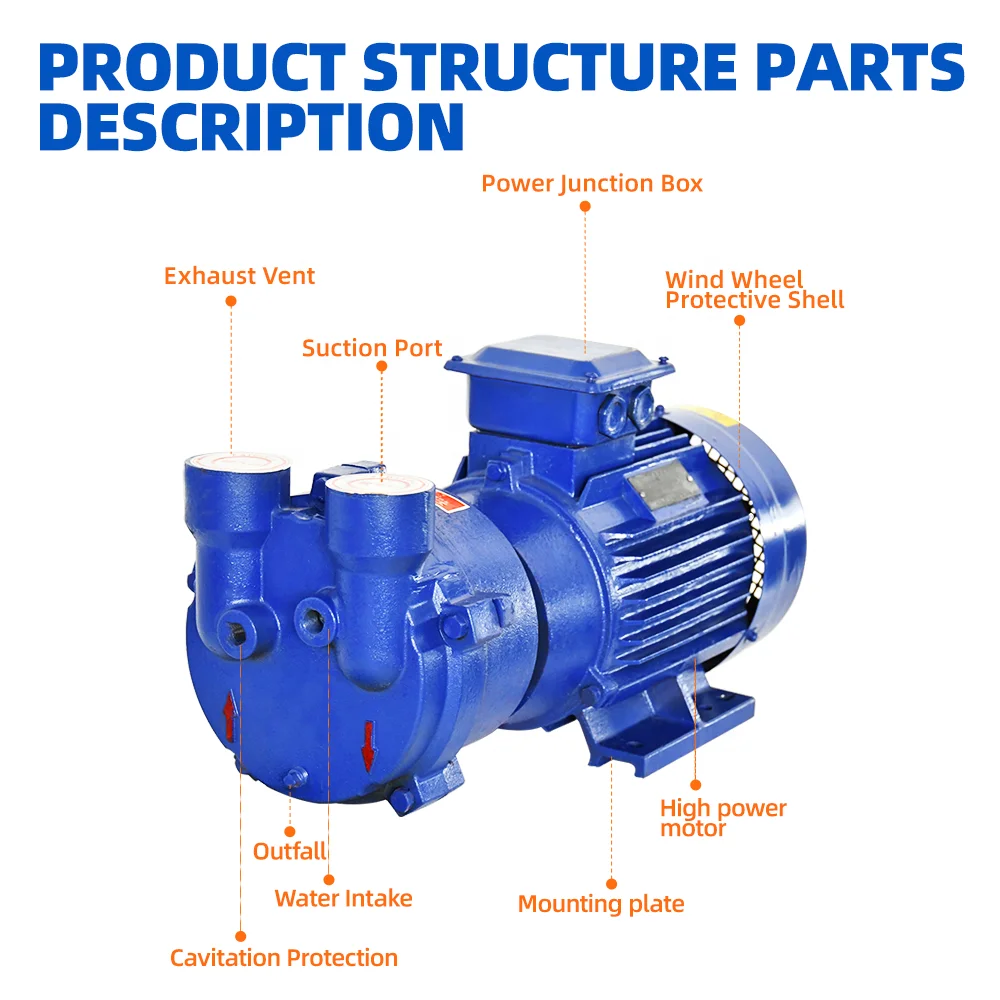

One of the key elements you should be looking for is the motor. The motor is what powers the fan blades and, therefore, how much air the machine can move. For those larger construction jobs or room spaces that require a lot of air circulation, you’re going to want the centrifugal air mover with a powerful motor capable of doing the job right. On the flip side, if you’re working in small spaces or don’t need as high a flow, smaller motor options could be just what you’re looking for.

One important element to take into consideration is the shape and size of fan blades. The centrifugal fans have various designs of fan blades such as straight, curved backward or radial types. Different blade designs are specifically intended to push air in different ways, so you’ll want the right blade design for your application because it can have a significant effect on their overall performance. For instance, flat blades are ideal for pushing air over a distance and curve-shaped blades are more suitable for circulating air in tight spaces.

have more than ten experienced designers R D engineers who each have more than 10 years experience in the centrifugal air moverresearch equipment and products. They can custom-design professional equipment and products meet the needs customers.

company has American ASME qualifications Chinese TS certification.the same time, has a group employees with over 10 years solid production experience, which guarantees reliability and quality our products, from mechanical equipment to operating. So far, it has loyal and stable centrifugal air moverfrom both United States abroad.

Established in 2012, company's parent is a highly professional enterprise integrating research and development vacuum machines and manufacturing and sales, with nearly 13 years of expertise in the industry of vacuum. With nearly 13 years industrial experience, business has solid centrifugal air moverproduction, procurement, and sales, and has built up the trust of its customers. We are able to provide our customers with best quality products and services for the most affordable prices due to our large-scale procurement standard production.

are a vacuum-related professional company that offers variety of business models meet the needs of different customers. include retail, wholesale customized processing. are able provide customers with the right design solutions their production equipment as well as high-quality products meet centrifugal air movercustomer's sites and production needs. company provides a complete range customized product solutions: starting with demand analysis, through product selection, draft design and installation equipment for production product production to product landing you to offer one-stop product customization service solutions for equipment vacuum.