var images = document.getElementsByTagName('img'); for (var i = 0; i < images.length; i++) { if (!images[i].getAttribute('alt')) { images[i].setAttribute('alt', ''); } }

¿Hay algún problema?

¡Por favor, póngase en contacto con nosotros para servirle!

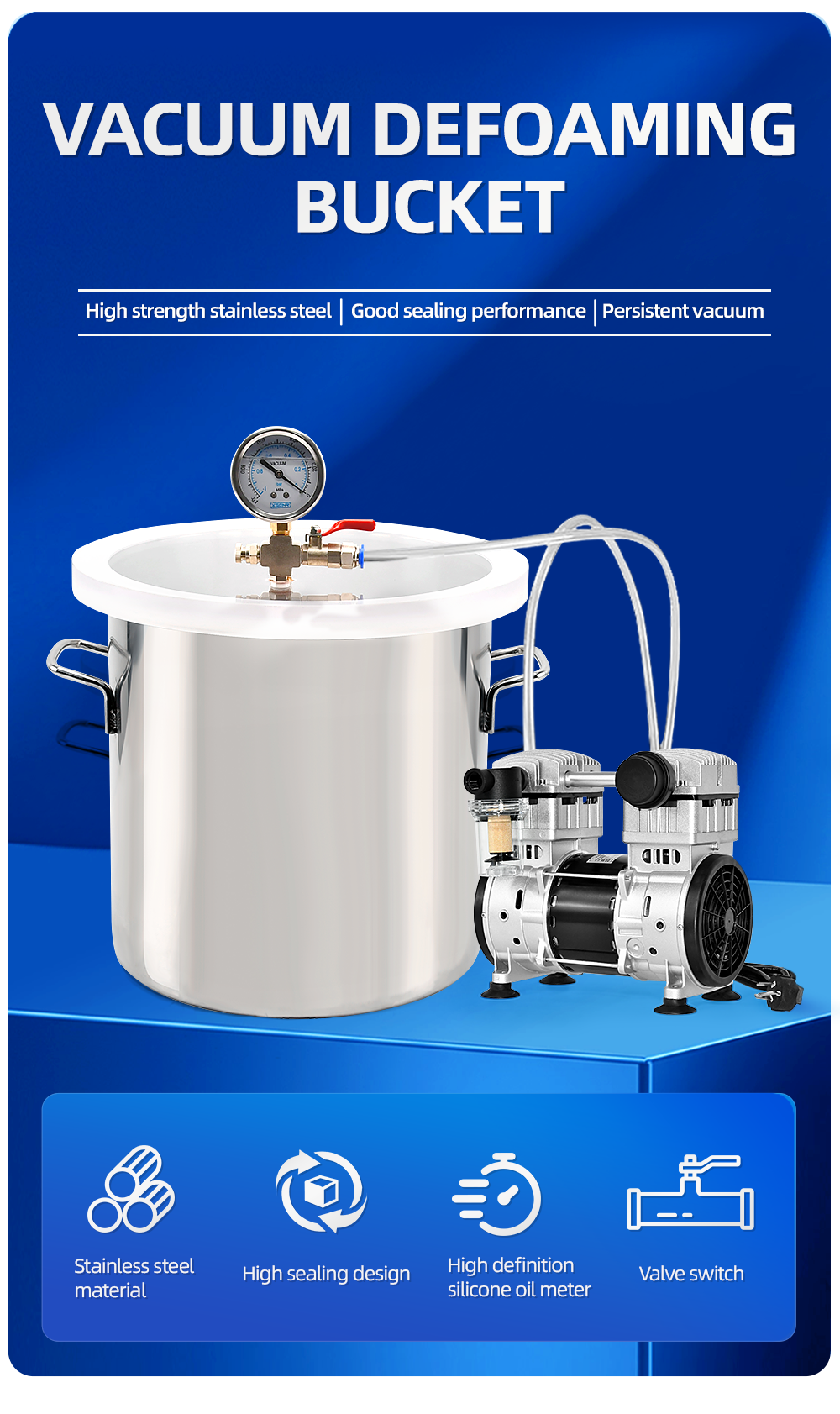

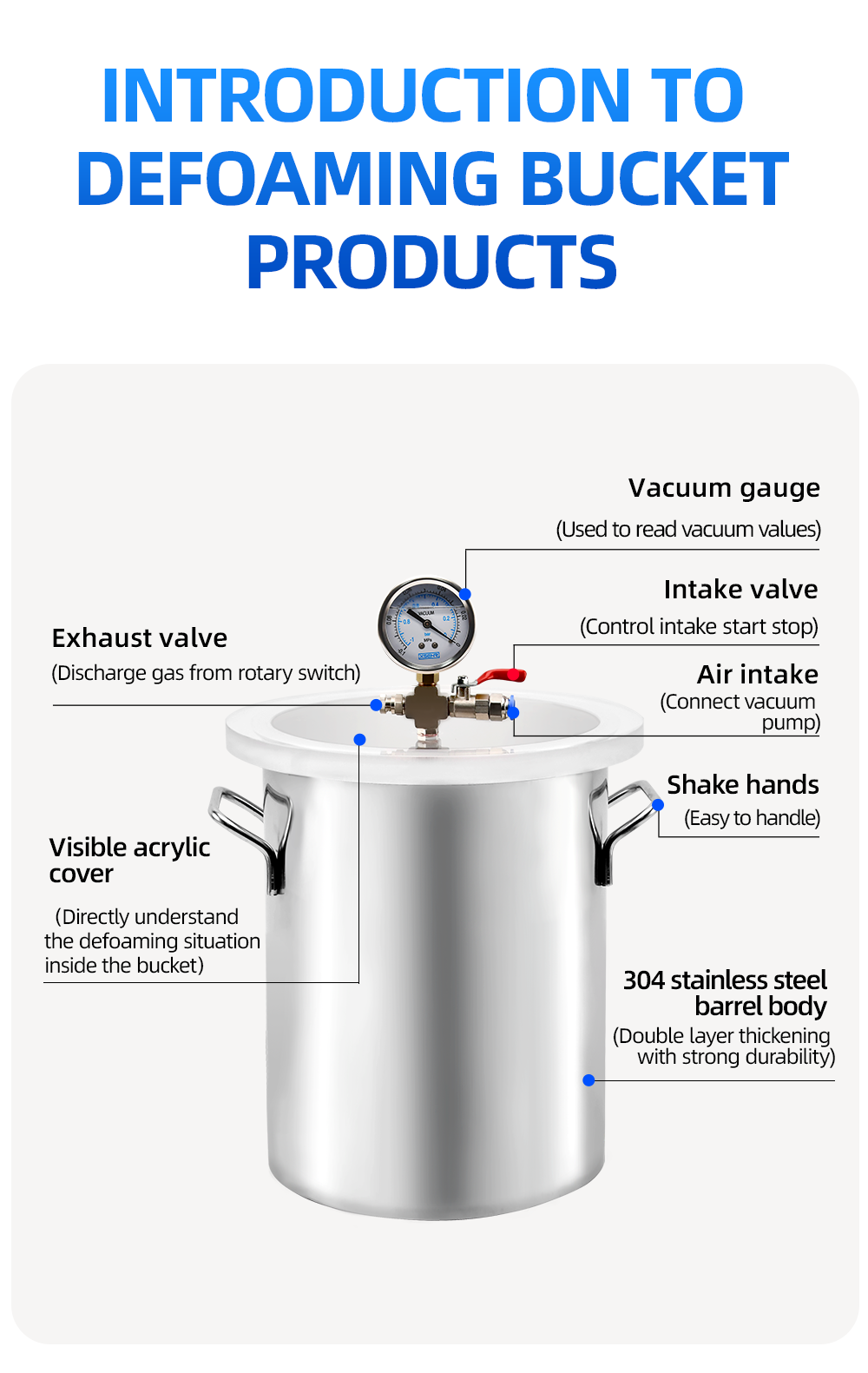

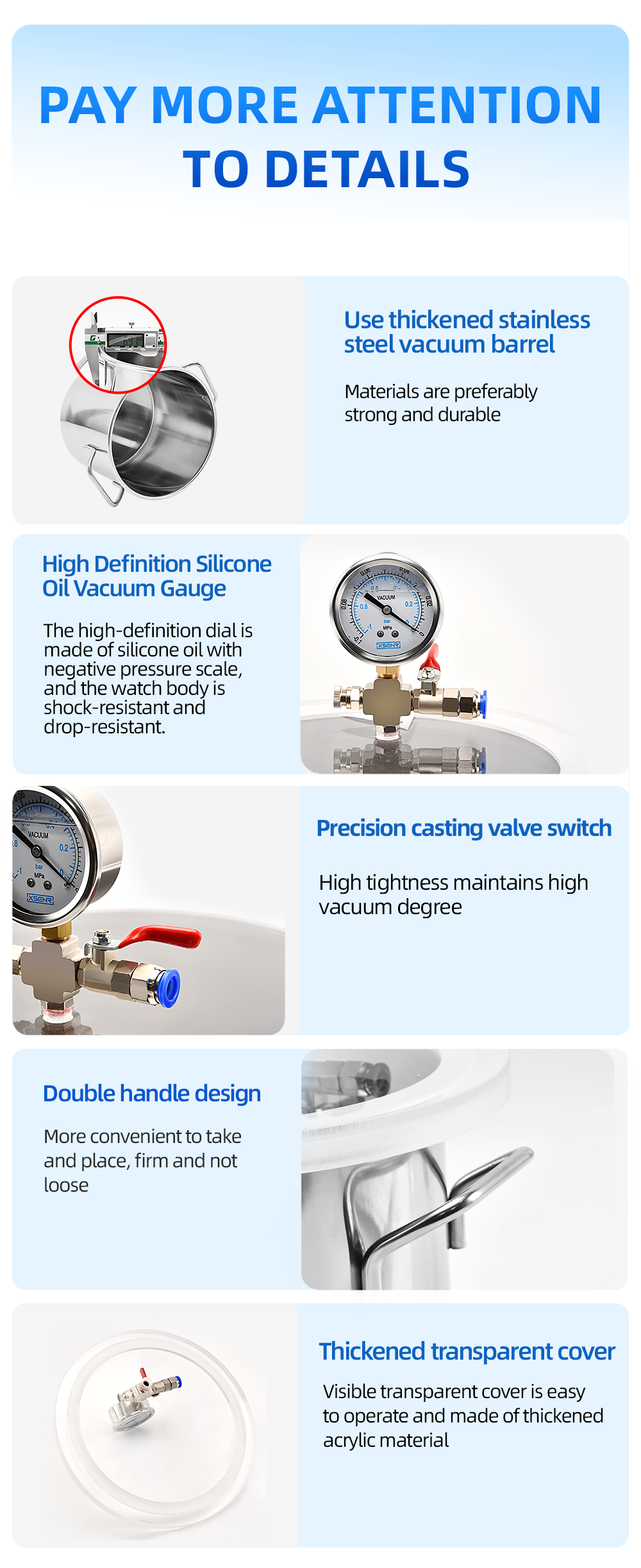

Es una capacidad de 15 litros hermética acero inoxidable cámara diseñada para desgasificar y desespumar líquidos viscosos (como epoxis, siliconas y pastas) sometiéndolos a vacío mientras los mezcla simultáneamente. La tecnología "sin aceite" bomba de vacío garantiza que no haya contaminación, y la tapa transparente permite monitorear visualmente todo el proceso.

Esta máquina es indispensable en cualquier industria donde las microburbujas provocan fallos en el producto :

Fabricación Electrónica: Preparación pasta de soldadura , tintas conductoras , compuestos de sellado epoxi , y resinas de encapsulado para PCB y microchips.

Compuestos Avanzados e Investigación: Desgasificación siliconas , uretanos , resinas epoxi , y geles para fundición, moldeo y prototipado.

Fotovoltaica: Producción de recubrimientos para celdas solares sin burbujas recubrimientos para celdas solares y adhesivos .

Dispositivos Médicos e I+D Farmacéutico: Mezcla y desgasificación polímeros biocompatibles y geles sin contaminación.

Dental y joyería: Creando piezas impecables resinas transparentes y materiales para fundición en cera perdida .