Чому повітряні баки CE набагато дорожчі за звичайні повітряні баки?

Під час замовлення нестандартних повітряних баків від повітряний бак заводу, клієнти помічають, що баки-ресивери CE значно дорожчі за звичайні накопичувальні баки. Це певним чином додана цінність безпеки, якості, нормативних вимог та брендингу. Клієнти платять не лише за сталь і виготовлення бака, а й за юридично підтверджену гарантію безпеки.

Ось кілька основних причин, чому накопичувальні баки CE коштують дорожче:

1. Основна причина — це суворі витрати на сертифікацію та відповідність вимогам

- позначка СЕ є «паспортом» для повітряних балонів, щоб вийти на ринок Європи. Це не просто сертифікація якості, а юридично обов’язкова позначка, яка свідчить про те, що повітряний балон відповідає Директиві щодо тискового обладнання (PED) 2014/68/EU.

- Сертифікація повітряного балона з позначкою СЕ передбачає складний процес. Повітряні балони поділяються на різні категорії ризику (A1,A2,G) залежно від таких параметрів, як розрахунковий тиск і об’єм. Для вищих категорій діють суворіші вимоги.

- виробникам повітряних балонів потрібно підготувати великий обсяг технічної документації для перевірки, включаючи детальні розрахунки конструкції, оцінку ризиків, сертифікацію матеріалів, документи системи контролю якості тощо.

- Повноважені органи проводять ретельні перевірки на місцях та регулярний моніторинг завод повітряних резервуарів системи управління якістю.

- заводу повітряних балонів необхідно залучати повноважний орган ЄС для проведення аудитів, випробувань та сертифікації, що є дуже дорогим і передбачає постійні щорічні внески.

2. Вищі стандарти проектування та виробництва

Стандарти проектування: Конструкція повітряного балона з СЕ має ґрунтуватися на стандартах EN, а також має враховувати термін експлуатації та безпеку в екстремальних умовах.

Вимоги до матеріалів: Усі сталі та матеріали для зварювання, що використовуються в повітряних балонах з СЕ, повинні мати документально підтверджене походження та відповідати директивам ЄС щодо матеріалів. Діють суворі вимоги до хімічного складу матеріалу, механічних властивостей, ударної в’язкості та інших показників.

Зварювальний процес та зварювальник кваліфікація: зварювальні процеси мають пройти ретельну оцінку та сертифікацію. Зварники повинні мати кваліфікаційний сертифікат зварника, який визнано в ЄС (наприклад, відповідно до ISO 9606 або EN 287).

Зварні шви мають піддаватися неруйнівному контролю у більш високій пропорції (наприклад, рентгенівське або ультразвукове дослідження), яке має виконуватися та оцінюватися кваліфікованим персоналом.

3. Відмінний контроль якості та можливість відстеження

Контроль якості на всіх етапах виробництва :Від поставки матеріалів, різання, гнуття, зварювання, складання до остаточного тестування — кожен етап документується.

Висока прозорість : Кожен повітряний балон має унікальний ідентифікатор (табличку з назвою та серійним номером), що дозволяє відстежувати кожну сталеву пластину, зварника та запис перевірки.

4. Сувора перевірка перед відправленням :

Гідростатичне випробування: Тестові тиски значно перевищують робочий тиск повітряних балонів, забезпечуючи цілісність конструкції балона в екстремальних умовах.

Тест на герметичність: Забезпечує відсутність витоку за будь-яких умов.

Засоби безпеки : Допоміжні запобіжні клапани, манометри та інші аксесуари також повинні мати сертифікат CE для забезпечення точності та надійності роботи.

Через вищезазначені причини повітряні балони CE — це не просто ємності для зберігання, а надійна система безпеки. Тому їхня ціна значно вища, ніж у звичайних повітряних балонів.

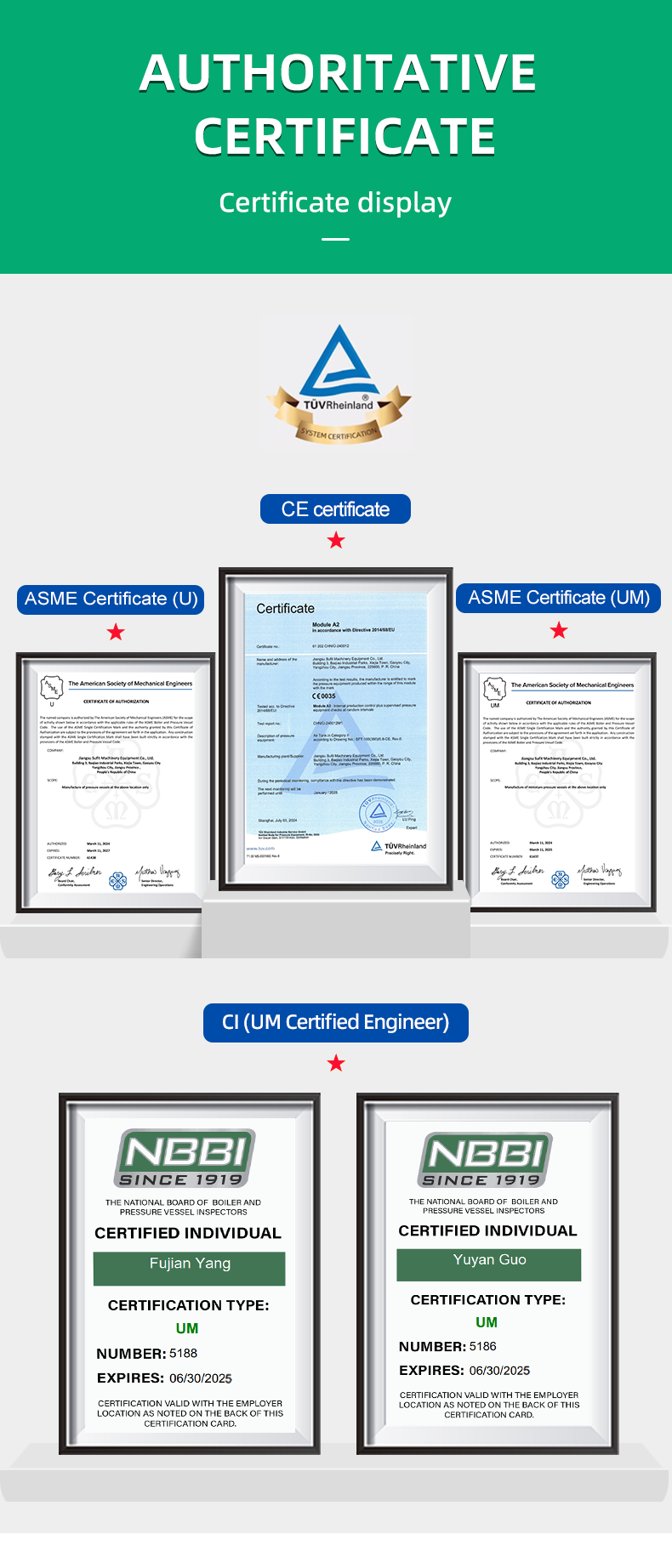

YCZX, як професійний завод з виробництва повітряних балонів, який займається виробництвом понад 10 років, отримав сертифікати CE на деякі повітряні балони, 20 л/30 л нержавіючу сталь повітряні балони, і 40 л / 50 л / 60 л / 80 л / 100 л балони з вуглецевої сталі. Для цих існуючих ресиверів не потрібно додатково оплачувати сертифікацію СЕ, але вони мають бути повністю ідентичними до існуючого дизайну.

Ласкаво просимо звертатися до YCZX для замовлення ресиверів з сертифікацією СЕ.