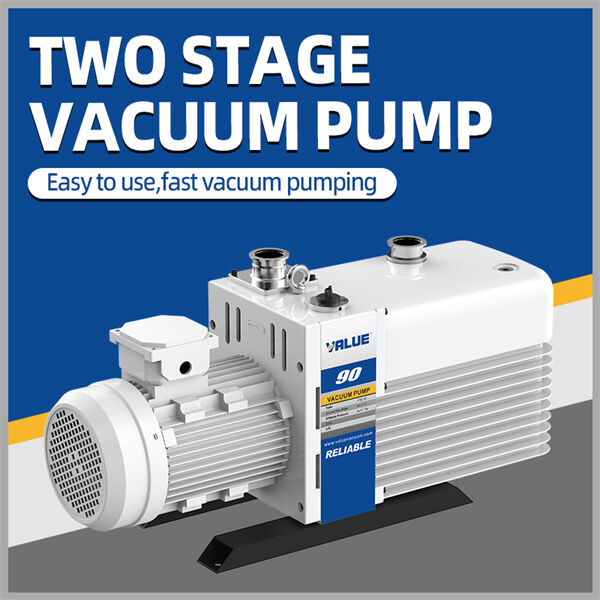

It is about the two stage vacuum pump, familiar? Behold is a novel tool with pp applications in diverse cultural and scientific arenas. Yeah, but I'll dig a little more into what those pumps do and why we care.

Consider this as a unit that just removes air/gas from an enclosed area to produce vacuum And consequently, it is called 2 idea Vacuum Pump. The first stage is manufactured by generator gears & vanes means decrease the pressure of air or gas within a grounded volume. A vacuum environment is one in which the pressure levels are considerably less than atmospheric, and it finds use in medical facilities, as part of industrial processes or if you see a science lab where certain experiments have to be performed under such circumstances.

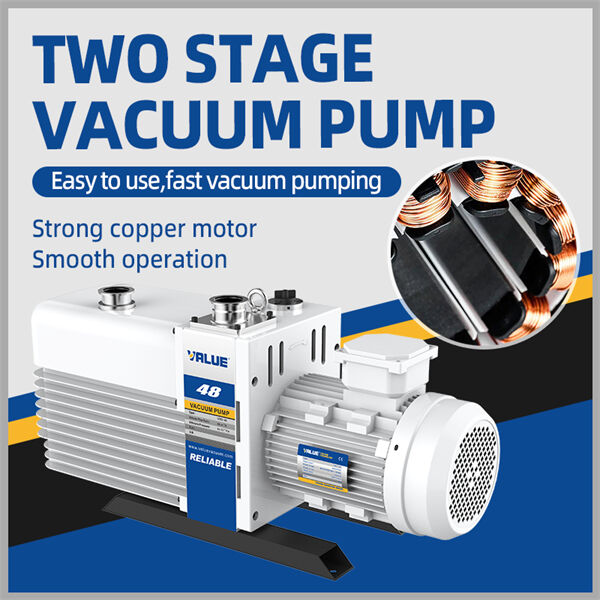

What Makes Two Stage Vacuum Pumps So Special? First off, they excel at fabricating some of the very best customized Valet Parking Systems for a few machines that perform their absolute best with high performance vacuums. These are reliable and long-lived options, 2-stage vacuum pumps. Those properties make it different from single-stage pump It uses less power compared to others So, in the over time, companies will also save on electricity costs.

If you are a businessman, then you can understand this words very well-two stage vacuum pumps is the only solution that works good for any industry. These pumps are supported with reduced maintenance that produce a smooth and hassle-free operations for longer period without any trouble on working state etc. Furthermore, they also consume less power than single-stage pumps that can mean big savings on your electricity bill in the long run. In Conclusion, you should know that the utilization of two stage vacuum pump in any operation will result several potential ways to cut-down expenses and save time for your business.

So what are two stage vacuum pumps really doing? These pumps use the principle of double gears and radiator vanes to reduce pressure in a no pass area (between two centrifuged liquids). Start With the air or Gas set to pulling- it is brought in from somewhere and then goes through a chamber. The compressed air or gas leaves both stages in this way, the first stage continues through to second part where it again compresses before exiting. In doing so, this two-stage process accelerates the removal of gas or air molecules in a volume and provides better vacuum performance.

The modern technology allows two-stage vacuum pumps in industrial application to be widely installed.

While these 2 phase vacuum pumps have been used for decades in industrial applications, the technology has now progressed to make them more powerful than before. Modern pumps have variable speed technology, which allows the pump to change its motor velocity based on different process scenarios (i.e. changes in flow rate/target head). This everyday feature not only saves energy but Prolongs the lifespan of your pump as well. Aside from that, modern high end pumps today are made with oil-less technology which eliminates the cost and effort of changing it throughout its service life. The result and hence vacuum pump of two stage also achieved to this made the same even more beneficial for all types corporate and industrial sectors as it provide high quality vacuums which can be now easily used in electrical, hydraulic worlds.

Therefore, it can be concluded that two stage vacuum pumps are those machines which definitely should have in our industrial ring while we discuss requirement of each area whether there you would certainly medical field or normal scientific. The pumps are needed to help enable technology advancement and operate more efficiently, at a lower cost for producing high-quality vacuums, in minimal time. Whether you are business indulged in choosing cheaper alternatives or someone exploring the new machines, this article on two stage vacuum pumps: what they do and how to choose a best option for all.

company accredited by both the Chinese TS and the American ASME. also have a group of experts with over 10 years working experience in manufacturing. guarantees reliability the quality all our products, from the mechanical equipment, employees. has a group of loyal and stable customers from both the two stage vacuum pumpStates and abroad.

are a professional vacuum company offering a variety business models that meet requirements various customers. These include: retail, wholesale customized processing. can provide customers with right design solutions for their production equipment as well as high-quality products to meet various customer's sites production two stage vacuum pump. offer a range customized product services such as demand analysis, product design, installation of production equipment, and production.

company employs team comprising more than 10 expert designers and R D engineers Each engineer has more than 10 years expertise in equipment and product research development, can customise various professional equipment and products meet various customer requirements two stage vacuum pumpcustomer needs.Meanwhile, have rapid response to sample requests which allows us to swiftly provide customers high-quality sample services.

parent company was established in 2012. It's professional business that incorporates research development, production, sale vacuum equipment. They have more than 13 years experience in the vacuum sector. company, with its almost 13 years of experience the two stage vacuum pumpis well-versed in sales, production, and procurement. It has also accumulated extremely loyal customer base. Large-scale procurement standardized production provide with huge cost advantages, we can offer customers the finest products and services most affordable prices.