Air Receiver Tank is also a crucial part of all Compressed air system. The Compressor tank: it stores the compressed air that other components operate on and makes sure you have ready access to your source of pressurized air when needed. In this vast array of air receiver tanks is the horizontal air receiver tank which admittedly has a rather straightforward and uncomplicated design.

That is, a horizontal air receiver tank which means it sits horizontally. It is in this way constructed since it can hold alot of the compacted air-so he to utilize as a part that requires through and travel strain. The tanks are horizontal, and they can contain more compressed air in comparison with a vertical tank so it provides high application flexibleness.

A Horizontal air receiver tank is the most needed to enhance for two good effects of performance and lasting life span at your compressed air system. On occasion those tanks are more extended and can hold a greater volume of packed air which implies when your system needs higher weight they discharge quicker letting substantially less slack time in. They are not very helpful in such situations where you need a constant and high-pressure air supply.

That much more the horizontal air receiver tank to cut down compressor cycling. It not only saves a lot of energy but also reduces the cycling, which is considered really bad for compressor life. This reduces maintenance requirements by limiting cycles on the compressor and, consequently extending system life.

On top of that, horizontal tank receivers allow for continuous and non-stop supply of compressed pneumatics tools-energy outputs to keep them in operation. It is the plug-and-play dream of automated office supply; a set tools operating smoothly and flawlessly on an uninterrupted stream of air pressure, making its wielders the fastest Undertakers in small manufacturing shops to sprawling industrial plants.

Horizontal Air Receiver Tanks Going Innovative

Horizontal Air Receiver tanks have been similarly designed and improved upon with material engineering advancements for the past several decades. These tanks present a far more durable, and are intended of over-blended steel than galvanized material. Furthermore, recent developments in technology of manufacturing has led to the production of smaller and lighter tanks that are also easy to install and maintain. As a part of the tank construction upgrades, these developments aid in improving overall compressed air system performance and life.

This is the reason why with horizontal applications like your vacuum trucks, combo trucks and etc must be paired by a right usage of an air receiver tank you always ensure as well that it will still operate fine together without worrying about any accident while maintaining its perfect condition. How to Be Safe with a Tankif you use tanks, safety tips

Stick to the maintenance, operation and safety inspection practices as your tank may work or function correctly.You are now, also increased priority should be pressure tank able to confirm in order for you then it was easier a meter probe.

Take care not to overpressurize tanks above rated pressures, as a tank rupture is very hard and potentially catastrophic.

Do a Visual and Physical Check of the HVAC system For any signs of damage, such as visible cracks or leaks which can be seen with your naked eye after visual check up then replace all damaged parts before they bring down complete House.

A horizontal air receiver tank is a statement in itself that you appreciate quality and performance, one that lasts long. A Tank is also expected to be a Heavy-duty tank with rugged construction that will help you maximize the value for every penny spent. Additionally, the best outcomes are obtainable when using a tank suitable for certain operational requirements.

Horizontal tanks are quite versatile and could easily fit in tight end spaces making it useful for automotive repair shops, manufacturing facilities or even at a construction site. These tanks are ideally built to produce power for different kinds of pneumatic tools and equipment, such as grinders, sanders or even nails guns - ensuring maximum work performance in multiple worksites with minimal interruption.

The Air Receiver Tank is key to keeping your compressed air system running smoothly and dependably so, in summary. With the exciting benefits, features and safety protocols as well quality standards across all of these products there is no other product that withholds so much value in an industrial context. These compressed air tanks provide assurance and are the perfect purchase for a compressor to excel at work.

2012, the parent company a professional business that a blend of research and development vacuum machinery as well as the sales and production vacuum equipment, has more than 13 years experience in the vacuum industry. With more than 13 years expertise in the field, company has stable experience in production, procurement, sales, and has horizontal air receiver tankan impressive list of customers who loyal. large scale of procurement standard production gives us massive cost advantages and can bring customers best products and services at most favorable prices.

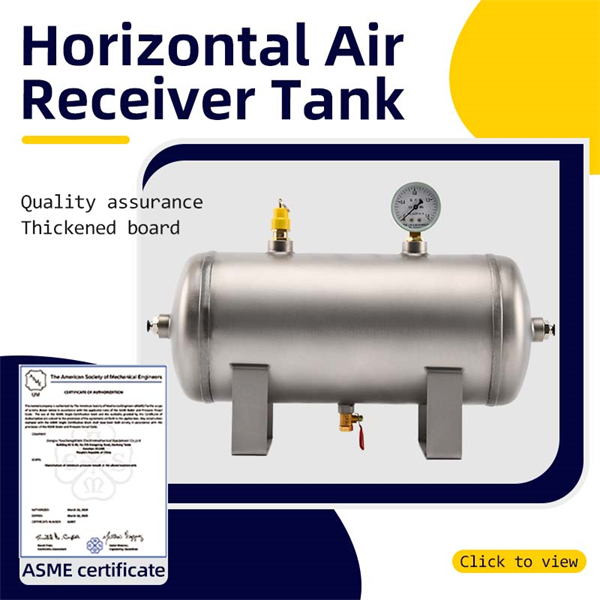

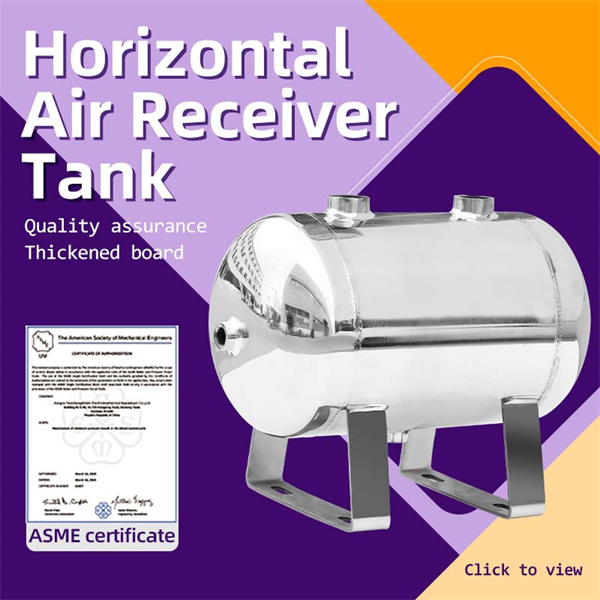

company has American ASME horizontal air receiver tankChinese TS certification.At the same time, it has a group employees with more than 10 years extensive production experience. This guarantees quality and stability our products, from mechanical equipment to operators. has loyal and stable clients both at home overseas.

We a professional vacuum company offering variety business models to suit demands of different clients. These include: horizontal air receiver tank, retail customized processing. are able to provide customers appropriate design solutions for production equipment as well as high-quality products meet different customer's site production requirements. offer a full array of custom-designed product services including demand analysis, design, installation of production equipment and product production.

company horizontal air receiver tankteam more than 10 professional designers and R D engineers over 10 years' experience in field of equipment and product research and development. can customize various professional products and equipment according to the needs different customers to meet customer needs.Meanwhile, we have an efficient sample response process enables us to quickly provide customers with high-quality sample services.