Челици за опрему за складиштење ваздуха

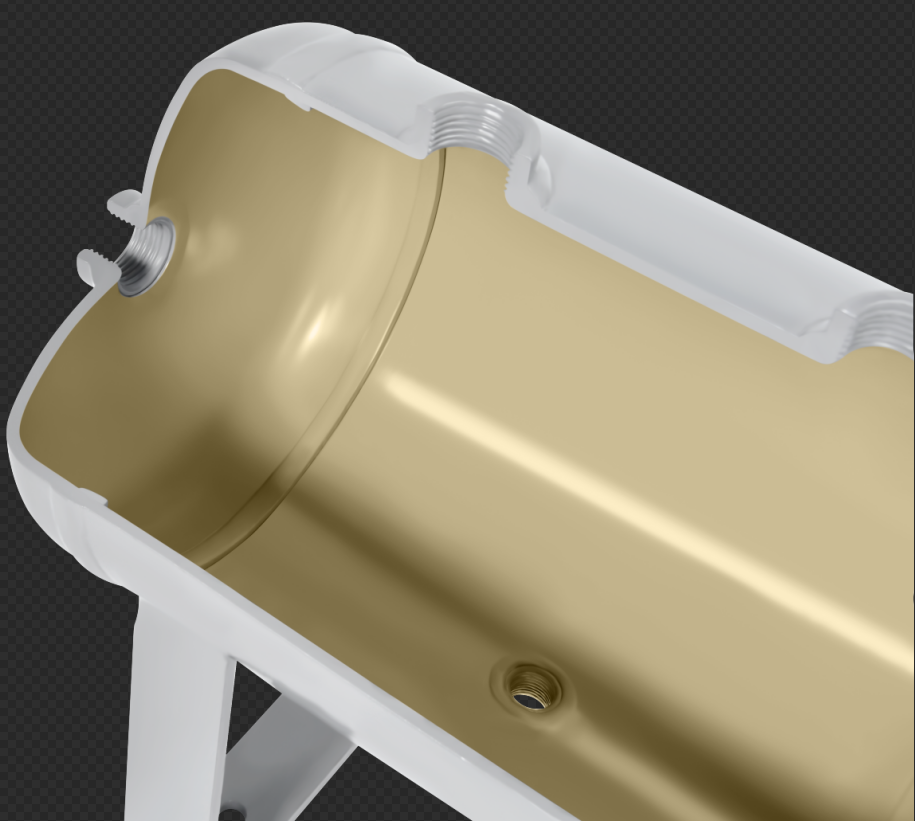

Угљенични челик је најчешће коришћени материјал од притисни судови (укључујући складиштење ваздуха резervoаре) због своје високе чврстоће, ефективности по питању трошкова и зрелог процеса производње. Међутим, угљенични челик постоје различите класе челика, а када се ради на по меру направљеном резervoару од угљеничног челика vazduh резervoар, kupci treba da navedu tačnu kvalitet vazduh proizvođaču rezervoara.

U prethodnom članku Како да приспособите резервоаре за складиштење ваздуха од произвођача резервоара за ваздух , pomenuli smo da rezervoari od ugljeničnog čelika складиштење ваздуха se proizvode obično od čelika Q235B i Q345R. U ovom članku ćemo navesti prednosti и neđavantazi ovih dveju kvaliteta , tako da kupci cAN napraviti правилно izbor prilikom personalizacije vazdušnog rezervoara .

КВ235Б

А občćan čelik. "Q" označava granicu tečenja, "235" ukazuje na granicu tečenja od 235 MPa, a "B" označava kvalitetni stepen, koji garancira udarnu žilavost pri 20°C.

Prednosti: Najniža cena, najbolja ekonomičnost i lako obradu.

Nedostaci:

- Niža čvrstoća , pa zahteva deblje zidove za vazduh cisterne at isti pritisak , ceo vazdušni rezervoar će biti težak .

- Relativno loša žilavost i otpornost na umor, posebno li osetljivost na niske temperature, lom risk .

- Loša otpornost na koroziju , лако за корозију.

Primena:

Погодно за резервоаре за складиштење ваздуха или других инертних гасова са ниским радним притисцима (обично ≤0,8 MPa) и малим запреминама. Користи се у ненапорним, мало захтевним апликацијама.

Q345R

Конструисан челик за судове под притиском. Његова граница течења је 345 MPa, значајно боља од Q235B.

Prednosti:

- Висока чврстоћа: При истом притиску, потребна дебљина зида је танја него код Q235B, чиме је rezervuar za čuvanje vazduha лакши.

- Изузетна ударна жилавост, висок ниво сигурности и велика отпорност на пуцање.

- Зрел процес: Конструисан специјално за судове под притиском, са стриктнијом контролом хемијског састава и механичких карактеристика, чиме се постиже изузетна заварљивост.

- Сагласност са прописима: Широко прихваћен и препоручен од стране кинеских и међународних стандарда за судове под притиском.

Nedostaci:

- Скупљи од Q235B.

- I dalje čelik sa ugljenikom, nije otporan na koroziju i zahteva unutrašnje prevlake za zaštitu od korozije (npr. epoksidna smola). Rezervoari za vazduh YCZX imaju unutrašnji premaz protiv rđe; ako kupac ima takve zahteve za prilagođene rezervoare za vazduh, molimo Vas da to navedete u početnoj komunikaciji.

Primena:

- Standardni i preporučeni materijal za većinu srednjeg i visokog pritiska (0,8 MPa - 3,0 MPa i više) rezervoara za vazduh i azot.

- To je glavni, siguran i pouzdan izbor na tržištu.

РЕЗИМЕ

Za većinu primena sa komprimovanim vazduhom, azotom i drugim inertnim gasovima, Q345R nudi najbolju ravnotežu sigurnosti, ekonomičnosti i performansi. Kada OEM i prilagođeni rezervoari za vazduh , navedite Q345R i zahtevati sertifikat materijala iz резервоар за ваздух proizvođača.

Ako je Vaš budžet jako ograničen, a radni uslovi su izuzetno jednostavni (niski pritisak, suv, nekritičan), Q235B takođe je dobar izbor. B ut budite svesni njegovih ograničenja.

NE није битно које класе челика са ниским садржајем угљеника се користе, интерна корозија donosi највећа безбедносна претња за vazduh резервоаре (узрокујући смањење дебљине зида и смањење чврстоће). Због тога, обавезно да резервоар vazduh има унутрашни антикорозиони премаз.

Након добијања резервоара за складиштење ваздуха од произвођача резервоара за складиштење ваздуха, купци такође морају строго да врше редовне прегледе (укључујући макроскопске прегледе, мерење дебљине и неразорне испитиве) , i брзо открију и дршкa проблеме корозије.