Perkembangan Industri Tangki Penyimpanan Udara/Air Spanyol

Berbeda dengan tangki udara yang menyimpan gas yang mudah terbakar, meledak, beracun, atau sangat reaktif, desain tangki udara yang menyimpan udara/gas inert/air lebih berfokus pada pencegahan kontaminasi dan menjaga kemurnian medium. Tingkat teknologi tangki semacam ini menunjukkan kemampuan suatu negara dalam manufaktur kelas atas, ilmu material, dan bahan kimia presisi.

Dengan mengintegrasikan ke dalam sistem standar Eropa, tangki penyimpanan udara/air buatan Spanyol telah menjadi sangat kompetitif di pasar-pasar yang menuntut ini. Perkembangannya terkait erat dengan industrialisasi, inovasi teknologi, dan peraturan keselamatan, serta telah melalui tahapan-tahapan utama berikut:

Pada pertengahan abad ke-20, tingkat industrialisasi Spanyol masih relatif rendah, sebagian besar menggunakan baja rendah- baja karbon . Baja karbon mudah berkarat saat digunakan untuk penyimpanan air, menyebabkan pencemaran air, korosi tangki, dan umur pakai yang lebih pendek. Lapisan pelindung karat interior sederhana memiliki efektivitas terbatas. Untuk udara/gas inert, tangki baja karbon akan teroksidasi di lingkungan lembap, serpihan oksida yang rontok akan mencemari kemurnian gas, sehingga tidak cocok untuk gas kemurnian tinggi.

Dari tahun 1970 hingga 1990, Spanyol mengalami peningkatan industri, baja tahan karat menjadi pilihan yang tak terhindarkan untuk aplikasi berstandar tinggi. Baja tahan karat 304 atau 316L secara sempurna menyelesaikan masalah korosi dan kontaminasi. Untuk tangki penyimpanan air, baja tahan karat 316L, karena ketahanannya yang unggul terhadap korosi klorida, menjadi pilihan standar untuk menyimpan air minum, air murni, dll. Bagian dalam tidak memerlukan lapisan pelindung, sehingga mudah dibersihkan dan didekontaminasi, menjamin kualitas air dalam jangka panjang. Untuk tangki gas inert, interior baja tahan karat yang sangat halus (seperti kelas EP dan BA) secara signifikan mengurangi adsorpsi gas dan outgassing, menjaga kemurnian gas tetap tinggi seiring waktu serta memenuhi kebutuhan industri seperti elektronik, farmasi, dan pengelasan kelas atas. Perlakuan pasivasi dinding bagian dalam menciptakan lapisan pelindung yang padat pada permukaan baja tahan karat, secara signifikan meningkatkan ketahanannya terhadap korosi. Ini merupakan proses standar baik untuk tangki air maupun tangki gas berkemurnian tinggi.

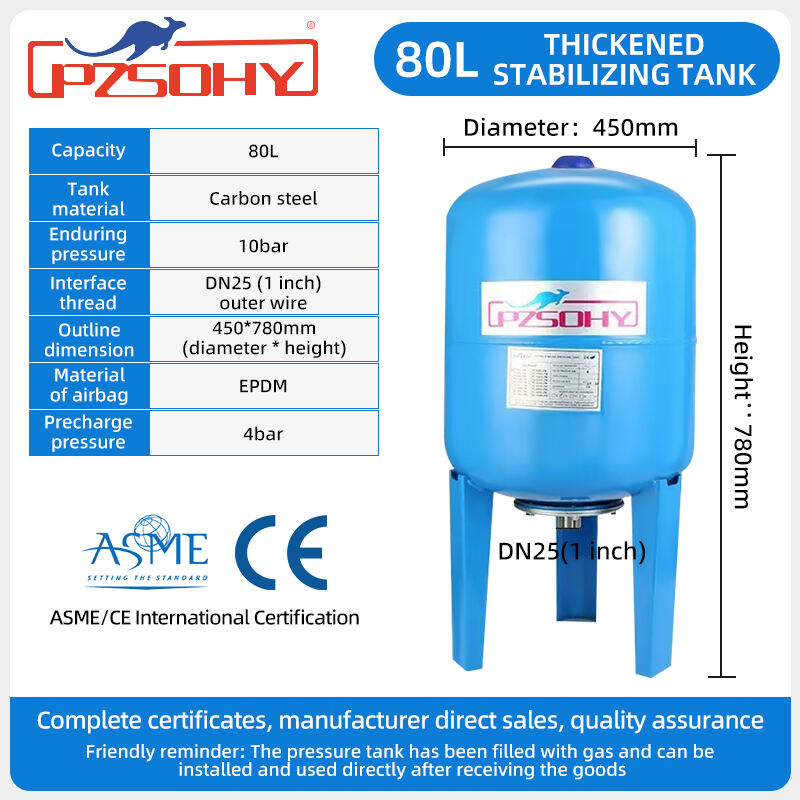

Sejak abad ke-21, desain tangki penyimpanan udara telah menjadi lebih khusus dan cerdas untuk memenuhi persyaratan kemurnian ekstrem di industri kelas atas. Selain baja tahan karat, Spanyol tangki udara juga mengembangkan tangki tekanan atmosfer (untuk sistem suplai air skala besar) dan tangki stabilisasi (untuk sistem suplai air dan boiler). Katup tangki penyimpanan gas inert kualitas tinggi menggunakan katup diafragma alih-alih katup globe konvensional untuk meminimalkan zona mati dan terperangkapnya gas. Semua antarmuka dirancang khusus untuk memastikan kedap udara dan kebersihan. Untuk tangki penyimpanan nitrogen cair dan argon cair berukuran besar, produsen tangki udara menerapkan sistem pemantauan level dan tekanan canggih, yang memungkinkan pengisian ulang otomatis dan peringatan jarak jauh. Analyzer kemurnian online terintegrasi pada port keluaran untuk pemantauan real-time kemurnian gas, memastikan kualitas dalam aplikasi akhir.