Pumpa rothair óil caidéil fhollaigh is málaíne ar leith atá ann a oibríonn trí ghleannanna rothlacha agus óil chun limistéar gan aer a chruthú. Leanann an t-óil na gleannanna mar a bhogann siad, ag cabhrú le sealadh beagnach foirfe a sholáthar ar an seomra inmheánach den mphumpa, ag cur deireadh le haon fholctha aer sa cheantar.

Is é sin féin a chuirfidh taca ar do roghaí nuair a théann tú ag roghnú uisce don phum. Is éagsúla gach uisce agus is é sin an ríomh atá idir na n-uisce, mar gheall air sin caithfidh tú cinntiú go bhfuil cineál fórmúla roghnaithe agat a dtabharfaidh an méid is fearr de do riachtanais phum. B'fhéidir nach mbeidh luasmeastachta cuid den n-uisce seo i gceart nó ró-trom nó ró-bheag, a chuireann taca ar conas oibríonn an phum. Ag críochnú, cinntigh go nglactar leis na léiriúcháin atá in éadan do phum roimh aon uisce a roghnú.

Teastaíonn cothabháil rialta de do ola rothlach é caidéil fhollaigh chun fáisnéis uasta a fháil as. Tá a fhios agat, cosúil le bacainn ola a sheiceáil agus súil a choinneáil ar scamluithe faoi bhun an ghluaisteáin... Cuimhnigh freisin go bhfuil tábhacht leis an bhfhuinneog a choinneáil glan agus saor ó bhruscair. Soláthraíonn an mhonaróir an fhaisnéis seo, chomh maith le moltaí eile ó thionscal na monaróireachta maidir le cothabháil an fhuinneoga.

Más éist tú le huibhreachaí speisialta aonáir, b'fhéidir go bhfuil an bpúmp ag luchtú agus tá sé amach chun cúpla fadhb a shocrú. Is fíor sinneacha comhaid, leiceadh na n-ainmhithe agus críocha blócaítte mar phríomhfadhbanna. Chun dearmad a dhéanamh ar díomá níos mó a thabhairt faoi leith don phúmp, caithfidh na fadhbanna seo a réiteach chomh luath agus is féidir.

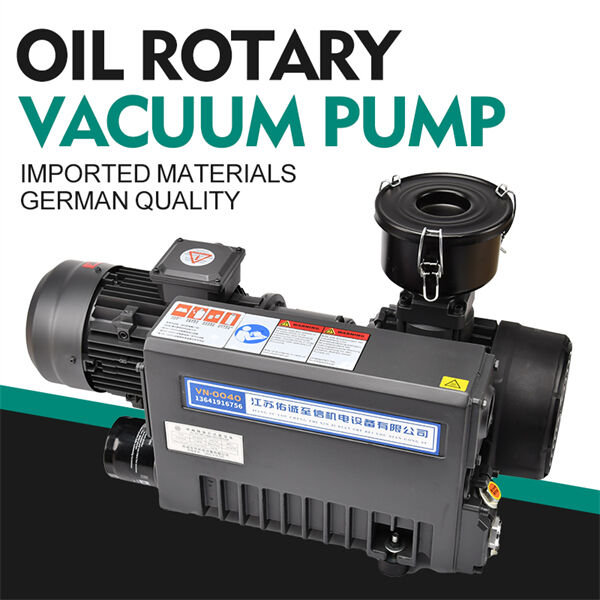

Tá go leor buntáistí ann nuair a úsáidtear ola rothlach caidéil fhollaigh i ngnéithe tionsclaíocha nó tráchtála. Is minic a oibríonn na fuinnoga seo gan stad ar feadh laethanta ar fad. Tá na gríosáin relatively inexpensive freisin agus tá na codanna atá le malartú ar fáil go héasca. Úsáidtear Oil Rotary Vacuum Pumps go minic i dtionscal, ionaid taighde agus clinici.

Mar chríochnú, ola rothlach caidéil fhollaigh faoi láthair neamh-iondúil i bhfeidhmchuíochtaí éagsúla tionsclaíocha agus tráchtála. Chun an mhaisín a úsáid go hiomlán, caithfidh na húsáideoirí tuiscint a fháil ar conas a oibríonn sé chomh maith leis an gcnaipe óil a úsáidtear agus conas córais choimeádta a dhéanamh, chomh maith le earráidí a réiteach nó a buntáistí a aithint. Ba chóir do na húsáideoirí seo treoracha a leanúint go cruinn chun blianta feidhmniú saor ó earráidí a fháil as do phumpa folctha rothair óil.

tá ceadúnais ASME Meiriceánacha ag an gcomhlacht agus tástáil TS Síneach. Ag an am céanna, tá grúpa oibrithe ag an gcomhlacht le níos mó ná 10 bliain taithí thar a bheith leathan ar tháirgeadh, rud a chinntíonn staballtacht na cáil ar na táirgí ó thiomáin mheicniúla go dtí na hoibrithe. Go dtí seo, tá grúpa d'airmheachtaí dúshlánaí oil rotary vacuum pump (pumpa vacuim rothartha ola) loyálta ag an gcomhlacht ar fud an domhain agus sa tír.

bunaíodh an chomhlacht mháthar sa bhliain 2012. Is comhlacht ghairmiúil í atá páirteach i bhfoghlaim agus i dtionscnaimh, i mbunaithe, agus i gceannach uirlisí vacuim. Tá timpeall is 13 bliain taithí aici sa réimse vacuim. Tá an comhlacht, le timpeall is 13 bliain taithí sa tionscail, go maith cliste i gceannach, i dtáirgeadh agus i n-órdú. Tá bonn d'airmheachtaí dúshlánaí loyálta leagtha aici freisin. Táimid in ann ár gcustaiméirí a sholáthar le pumpa vacuim rothartha ola ar ardchaile agus le seirbhísí ar an gcostas is ísle mar gheall ar tháirgeadh agus ar órdú ar scála mór.

cuideachta ola rotharach le fórsa vacuim: foireann le níos mó ná 10 dearthóir proifisiúnta agus innealtóirí R&D le breis is 10 bliain eolais sa réimse taighde agus forbartha ar thiomáiní agus ar tháirgí. Is féidir linn táirgí agus tomhaltóga gairmiúla éagsúla a chustamú de réir riachtanais custaiméirí éagsúla chun na riachtanais a shatisfá. I meánaimh sin, tá próiseas éifeachtach freastalaí sampla againn a chuireann in iúl go tapa go dtí na custaiméirí seirbhísí sampla ar ardchaile.

is cuideachta vacuim gairmiúil í atá ag soláthar raon leathan modhanna gnó a chomhlíonann riachtanais na gcustaiméirí éagsúla. I measc na modhanna sin tá ceannach i mbulk, beannacht agus próiseáil chustamaithe. Soláthraíonn an chuideachta réiteach díolacháin ar ardchaile do thiomhaltóga a bheidh comhoiriúnach le riachtanais an áit phróiseála. Soláthraíonn an chuideachta ola rotharach caidéil fhollaigh comhphacáiste réitigh seirbhís shaincheaptha táirge: tosú ar anailís éilimh, trí rogha táirge, dearadh samplach, agus suiteáil mhianais do tháirgeadh ó tháirgeadh táirge go dtí seoladh an táirge, ag soláthar réitigh uathu go léir a shaincheapann do tháirge do mhianais fhothabhartha.