tlaková nádoba pro hasicí systém

Tlaková nádrž pro hasicí účely hraje klíčovou roli v systémech zásobování vodou pro hašení požárů. Její základní funkcí je uchovávat a dodávat hasicí vodu za využití tlaku stlačeného vzduchu uvnitř nádrže. Nejedná se o velkou nádrž na skladování vody, ale spíše o zařízení, které díky předstlačení dokáže rychle a automaticky poskytnout tlakovou hasicí vodu v počáteční fázi požáru nebo při kolísání tlaku v potrubí.

Hlavní oblasti použití jsou následující:

- Vysoké budovy: Zajištění stabilního počátečního tlaku pro hasicí systémy v horních zónách a kompenzace netěsností v potrubí.

- Automatické sprinklerové systémy : Nezbytné zařízení pro stabilizaci tlaku ve všech mokrých automatických sprinklerových systémech.

- Hasicí hydrantové systémy / systémy hašení vodními tryskami a jemnou mlhou: Udržování denního tlaku v síti hasicích hydrantů.

- Malé samostatné hasicí systémy: Například rozvodny, místnosti pro komunikační zařízení atd. Nádrž na udržování tlaku lze přímo kombinovat s čerpadlem, čímž vznikne jednoduchý systém zásobování požární vody se stálým tlakem.

Hlavními funkcemi požární tlakové nádrže jsou udržování tlaku a doplňování vody. V automatických sprinklerových nebo hydrantových systémech musí být v potrubní síti udržován určitý tlak (např. 0,10–0,15 MPa). Pokud dojde k poklesu tlaku způsobenému drobnými netěsnostmi nebo změnami teploty, tlaková nádrž okamžitě vypustí malé množství vody pod tlakem, čímž kompenzuje ztrátu tlaku, zabrání častému spouštění hlavního požárního čerpadla, šetří energii a chrání zařízení.

V počáteční fázi požáru trvá spuštění hlavního požárního čerpadla a dosažení jeho jmenovitého průtoku určitou dobu (obvykle nejvíce 2 minuty). Během tohoto „okna“ tlaková nádoba poskytne 1–2 sprchovacím hlavicím nebo požárnímu hydrantu počáteční tlakovou vodu pro hašení požáru a tím získá cenný čas pro zásah.

Pracovní princip:

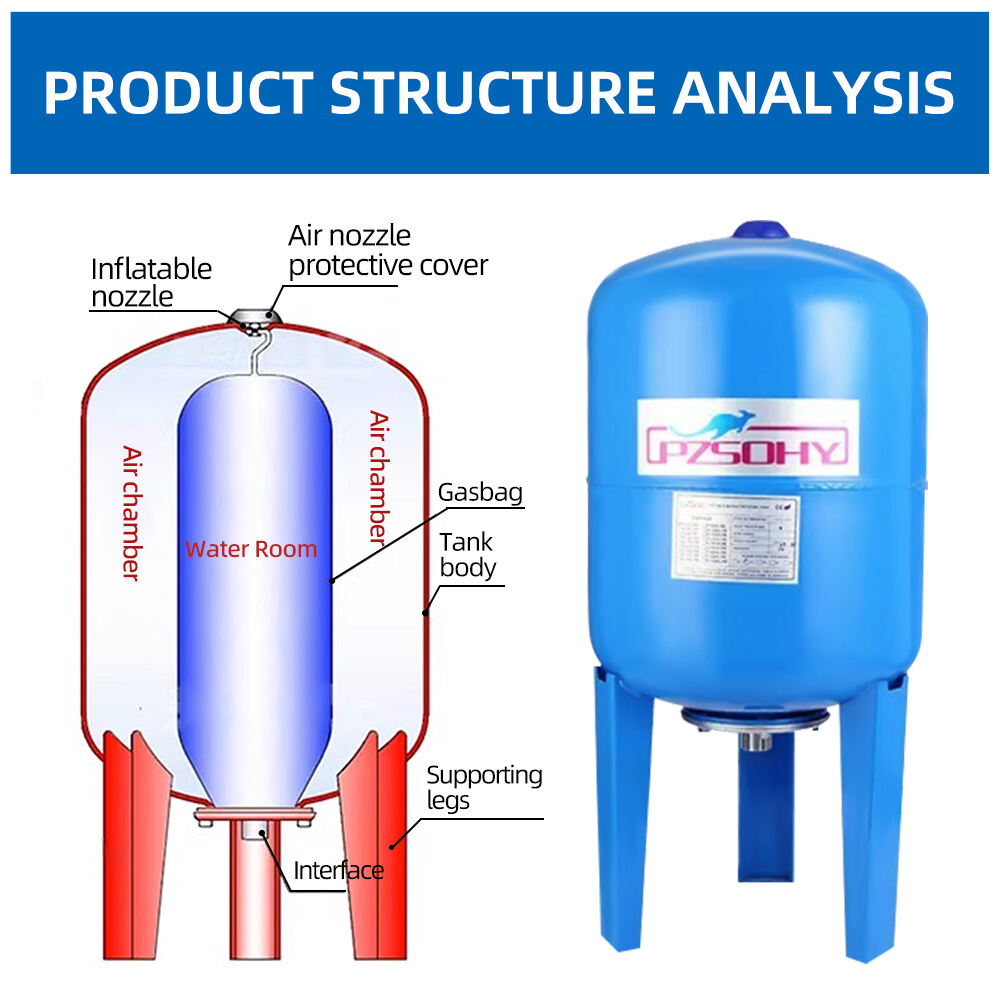

Tlaková nádoba obsahuje gumový kapsle (membránu), která ji dělí na dvě komory: plynovou komoru (horní část, naplněnou dusíkem nebo vzduchem) a vodní komoru (dolní část, připojenou k potrubní síti protipožární ochrany). Po instalaci systému je plynová komora nejprve předplněna na určitý tlak (P₀), který je obvykle rovný nebo mírně nižší než minimální provozní tlak vyžadovaný potrubní sítí protipožární ochrany.

Za normálních provozních podmínek je potrubní systém protipožární ochrany naplněn vodou a tlak je stabilní. V tomto okamžiku je také vodní komora nádrže plná, plynová komora stlačená a tlak je vyrovnaný s tlakem v potrubní síti. Pokud dojde k malému úniku v potrubní síti nebo k poklesu teploty, který způsobí snížení tlaku, stane se tlak v plynové komoře uvnitř nádrže vyšším než tlak v potrubní síti. To okamžitě stlačí membránu a vytlačí vodu z vodní komory do potrubní sítě, čímž se tlak stabilizuje. Tento proces probíhá okamžitě a automaticky a nepotřebuje spuštění čerpadla. Pokud tlak nadále klesá (což signalizuje významný únik nebo začátek požárního zásahu), když hladina vody v nádrži klesne na minimální nastavenou hodnotu a tlak klesne na startovací tlak hlavního požárního čerpadla, aktivuje se tlakový spínač a automaticky spustí hlavní požární čerpadlo. Hlavní čerpadlo dodává vodu pro hašení požáru a současně se část vody vrátí zpět do tlakové nádrže, čímž ji znovu naplní pro příští provoz.

Výhody:

- Rychlá reakce okamžitá odezva na tlakové výkyvy bez nutnosti čekat na spuštění motor čerpadla.

- Ušetření energie a ochrana životního prostředí: Účinně snižuje časté spouštění hlavního požárního čerpadla a čerpadla pro udržování tlaku, čímž se prodlužuje životnost zařízení.

- Zajišťuje počáteční hasení požáru poskytuje zásadní první přívod vody pro evakuaci personálu a počáteční potlačení požáru.

- Vysoký stupeň automatizace: Plně automatický, nevyžaduje žádný ruční zásah.

Omezení:

- Omezená zásoba vody nelze použít jako primární zdroj požární vody; jeho kapacita zásoby vody je obvykle dostatečná pouze pro počáteční hasení požáru nebo udržování tlaku.

- Vyžaduje pravidelnou údržbu vyžaduje pravidelné kontroly, aby bylo zajištěno, že je membrána nepoškozená a tlak vzduchu je v normě.

Jako profesionální výrobce tlakových nádob již více než 12 let vyrábí společnost YCZX různé tlakové nádoby a vyrovnávací nádoby pro požární systémy a výrobce. Kontaktujte nás pro výrobu tlakových nádob na míru pro požární zařízení.